Planetary Gear Motor

Planetary Gear motor is a DC motor with Planetary gearbox. DONGMING Provide Precise Planetary Gear Motor with Low Noise Long Lifespan, High Torque, High Efficiency, High Quality. Offered in Standard or Customized Solutions for Planetary Gear Motor.

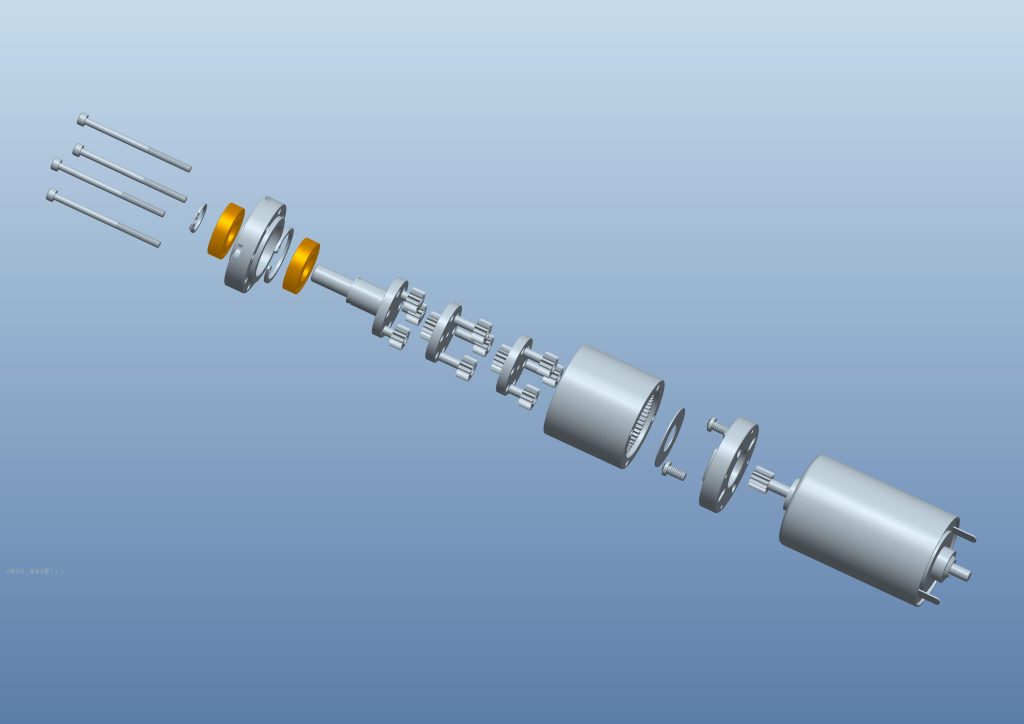

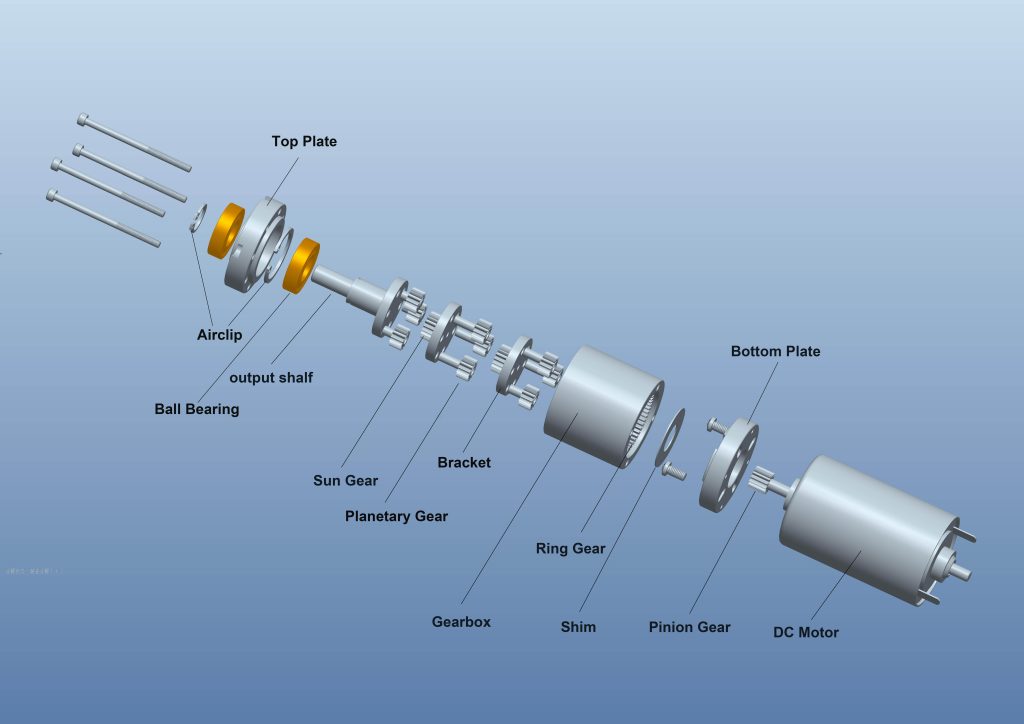

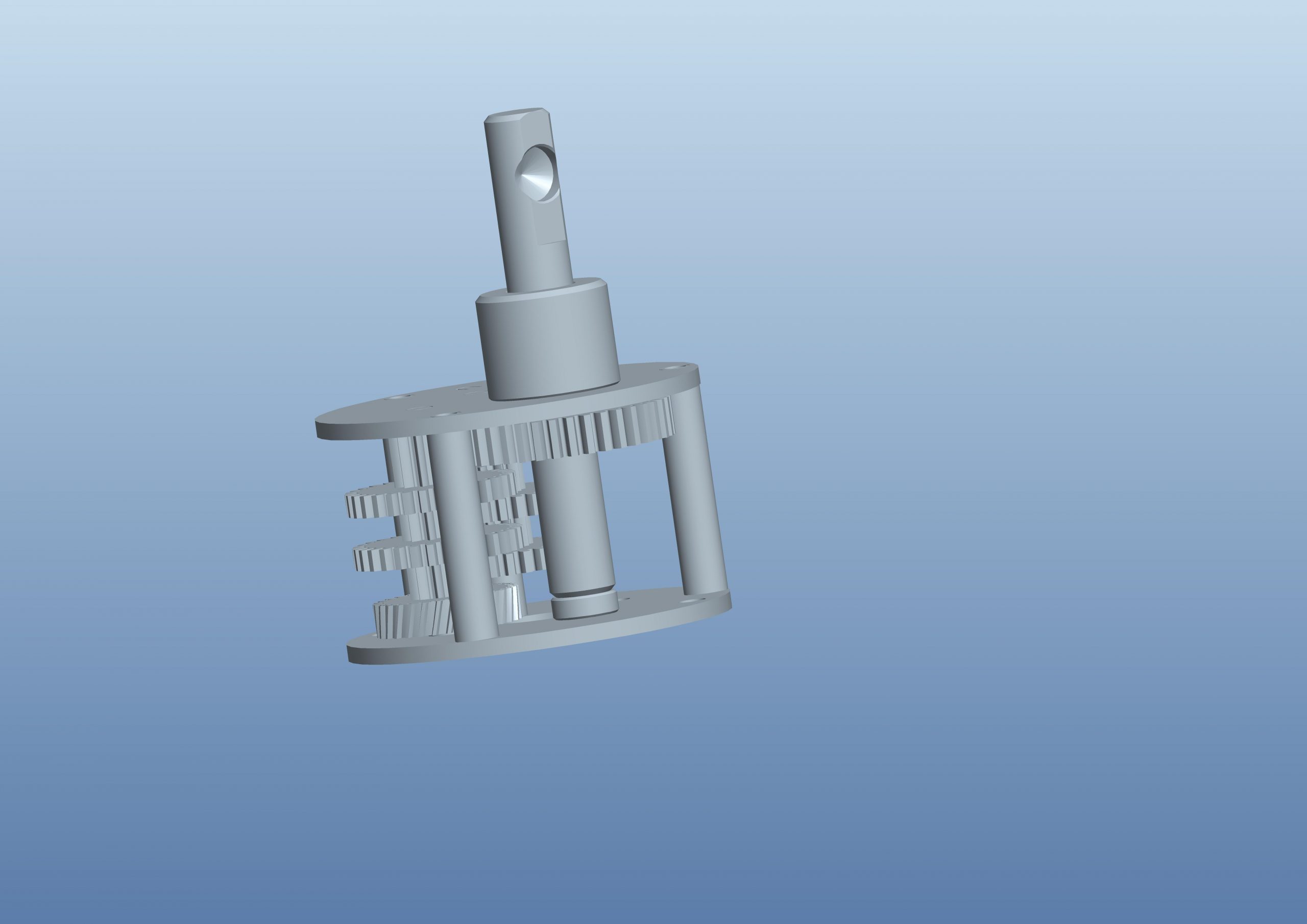

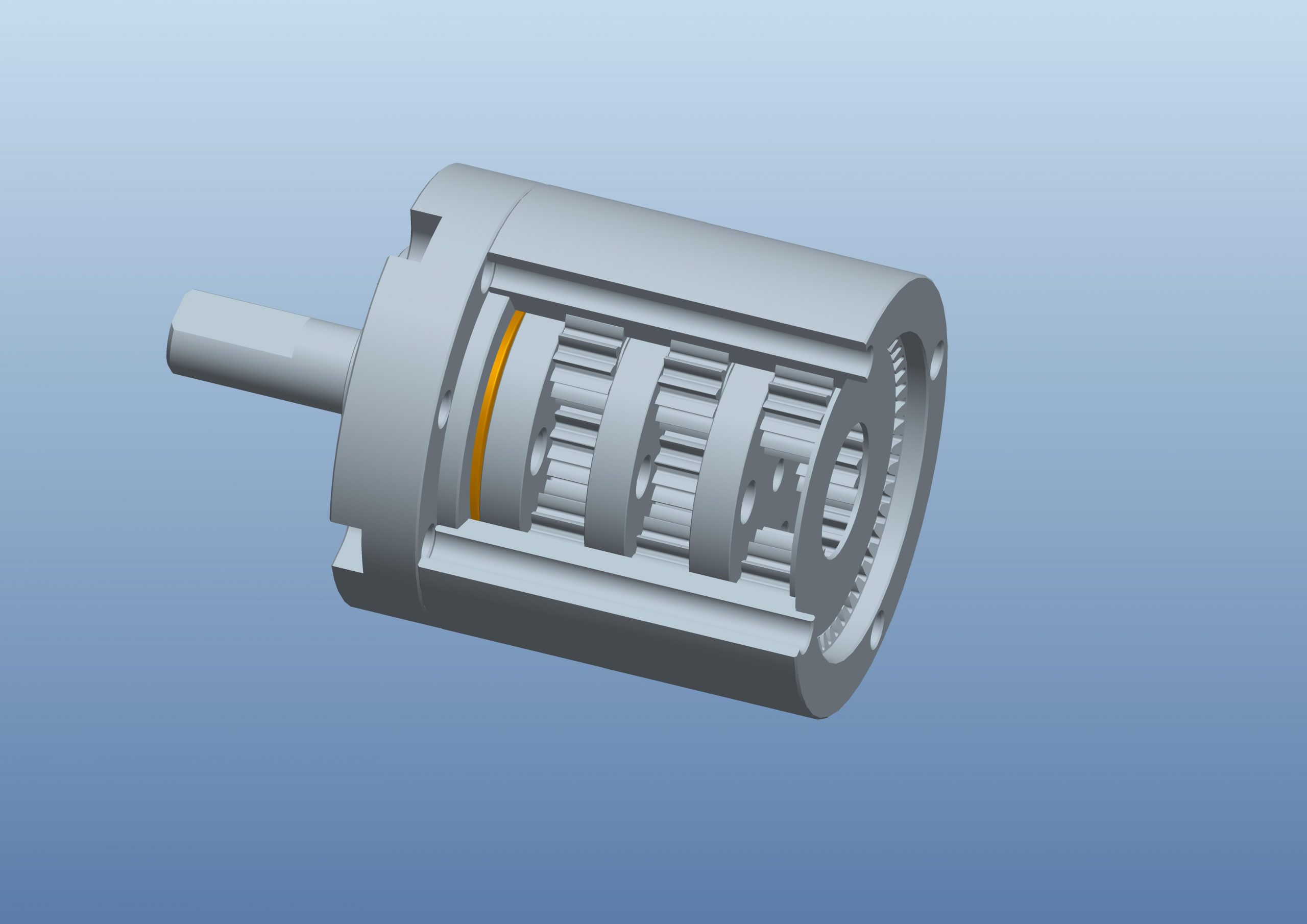

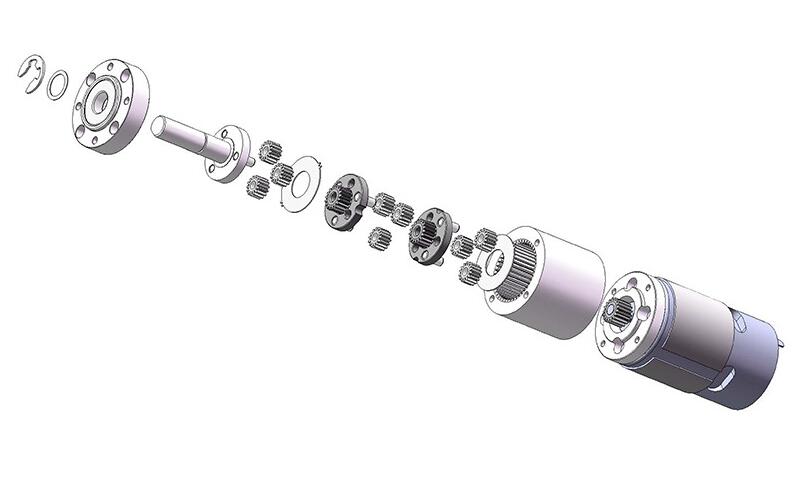

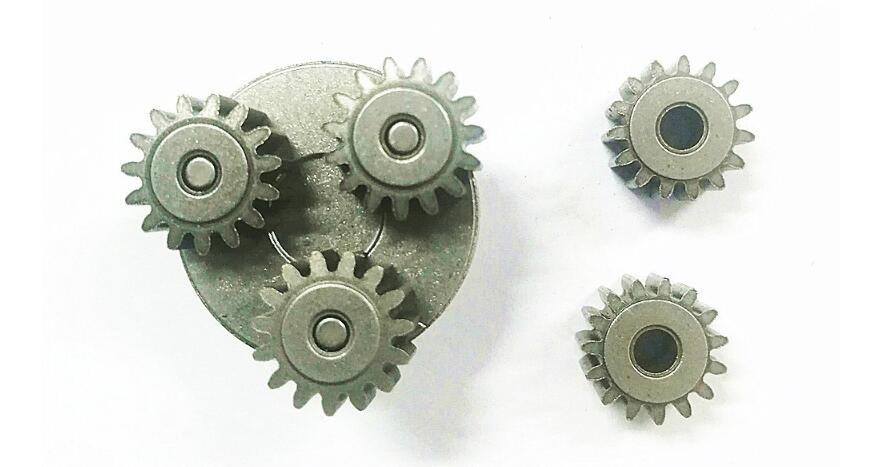

The gears inside of a planetary gear head have a unique method of meshing together. They have an internal gear, called the sun gear. The sun gear drives multiple outer gears known as planetary gears. The planetary gears mesh with an outer ring to guide and hold them in place. The outer ring is fixed and incorporated in the motor housing.

DC Planetary Gear Motor

Planetary Gear Motor Machining

Diamater: 16mm

Voltage: 3V~12VDC

Speed: 3RPM~1600RPM

Torque: 0.03kg.cm~4.80kg.cm

DC Planetary Gear Motor Machining

Diamater: 16mm

Voltage: 3V~12VDC

Speed: 3RPM~1600RPM

Torque: 0.03kg.cm~7kg.cm

DC Planetary Gear Motor

Diamater:16mm

Voltage: 6V~24VDC

Speed: 3RPM~2000RPM

Torque: 0.03kg.cm~8kg.cm

DC Planetary Gear Motor

Diamater: 22mm

Voltage: 6V~24VDC

Speed: 3RPM~1000RPM

Torque: 0.25kg.cm~8kg.cm

DC Planetary Gear Motor

Diamater: 22mm

Voltage: 6V~24VDC

Speed: 3RPM~1500RPM

Torque:

0.18kg.cm~26kg.cm

DC Planetary Gear Motor

Diamater: 24mm

Voltage: 6V~24VDC

Speed: 3RPM~1500RPM

Torque:

0.18kg.cm~8kg.cm

DC Planetary Gear Motor

Diamater: 28mm

Voltage: 6V~24VDC

Speed: 3RPM~1500RPM

Torque: 0.3kg.cm~30kg.cm

DC Planetary Gear Motor

Diamater: 28mm

Voltage: 6V~24VDC

Speed: 3RPM~1500RPM

Torque: 0.5kg.cm~40kg.cm

DC Planetary Gear Motor

Diamater: 28mm

Voltage: 12V~24VDC

Speed: 3RPM~500RPM

Torque: 0.5kg.cm~50kg.cm

DC Planetary Gear Motor

Diamater: 32mm

Voltage: 12V~24VDC

Speed: 3RPM~1500RPM

Torque: 0.5kg.cm~40kg.cm

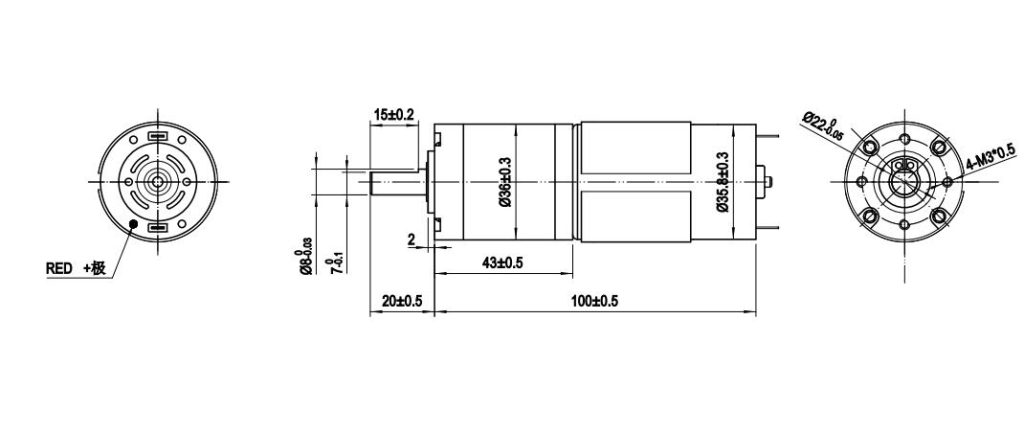

Planetary Gear Motor

Diamater: 36mm

Voltage: 12V~24VDC

Speed: 2RPM~1500RPM

Torque: 1kg.cm~50kg.cm

DC Planetary Gear Motor

Diamater: 36mm

Voltage: 12V~24VDC

Speed: 2RPM~1500RPM

Torque: 1kg.cm~60kg.cm

DC Planetary Gear Motor

Diamater: 42mm

Voltage: 12V~24VDC

Speed: 4RPM~1000RPM

Torque: 1kg.cm~80kg.cm

DC Planetary Gear Motor

Diamater: 42mm

Voltage: 12V~24VDC

Speed: 4RPM~800RPM

Torque: 1kg.cm~80kg.cm

DC Planetary Gear Motor

Diamater: 52mm

Voltage: 12V~24VDC

Speed: 4RPM~570RPM

Torque: 3.7kg.cm~500kg.cm

DC Planetary Gear Motor

Diamater: 56mm

Voltage: 12V~24VDC

Speed: 4RPM~500RPM

Torque: 3kg.cm~1000kg.cm

Benefits of DC Planetary Gear Motor

- High Torque, High Detent Torque, High RPM, Low Noise, Small Backlash, High Precision

- Durable and High efficiency, Small Cogging Torque

- Compact size, Customized Shaft direction

- High Durability, Waterproof, Long Lifespan

- Higher Speed Range, buit-in Driver

Why Choose DONGMING MOTOR

Innovative R&D Engineering for Your Project

- Considering the rationality and convenience of the production process from the design stage.

- If our existing “standard” DC gear motor cannot provide the optimal performance, we R&D team will work with you to develop customized DC gear motor solution.

Modernized High Volume Manufacturing

4+ semi-automatic production lines, 2400000PCS DC gear motors/month

Quality & Reliability Policy

- Considering the rationality and convenience of the production process from the design stage

- Adopting the international advanced quality management system, strict management of IQC, production and QA

Effective Communication and Collaboration

- Customer needs analysis team respond to customer quickly and professionally

- Professional sale engineers provide one-stop customized services

Professional R&D engineer team work for you

From developing&research, prototype, testing, small batch test, mass production and after-sales service

Start the Custom Service for DC Planetary Gear Motor

Requirements discussion

To ensure providing the best solution of DC gear motor, the sales engineers should discuss with customer some important infomation including:

- The installation dimension for DC gear motor

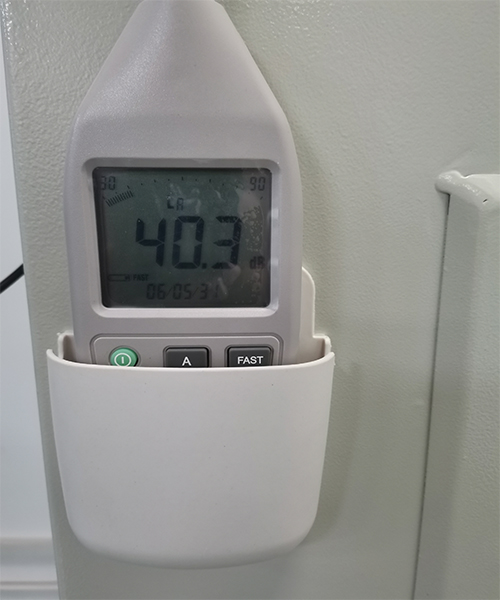

- The parameter for DC gear motor includes operation load speed, operation load torque, voltage, output load current,stall torque, stall current, work cycle, working condition, noise level, lifetime,Electromagnetic shielding, etc

- The certification requirements, such as CE, ROHS, SGS, TEACH.

- The target cost and project plan.

Project Evaluation

According customer’s requirments for DC gear motor and other information of project, our R&D team analyst and evaluate the project. And to confirm provide our exsiting solution or build a new solution. If to design a new DC gear motor, DONGMING design team will provide the project evaluation report for the development time, mold cost and risk.

Prototype sample manufacturing

To confirm all requirements with customers step by step, our R&D will utilize the design software to design a product or set a 2D/3D drawing for DC gear motor.

Sample performance test

When the sample is completed, our R&D team will test the DC gear motor’s all performance with our precise test equipment. If customers have lifetime requirement, we will provide the lifetime cycle test in laboratory.

Small batch production and mass production

Start a trial production after sample working perfectly on product. Launch small batch to test customers’ market.

Finally start the mass production

We have the compeleted quality control system for production.

Delivery and after-sales service

When products ready to ship, we are also responding for logistics to make sure customer picks up all products satisfied.

If customers have any issue after sales, our team will support to solve it always.

DC Planetary Gear Motor Types

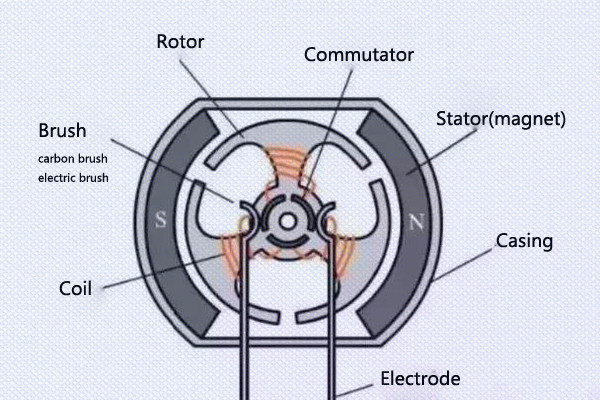

Brushed DC Motor

Brushed DC motors work by having the coil rotate inside the surrounding magnets. The rotation of the coil causes the contact between commutator and brush to alternate, therefore switching the current flow through the coil. As a result, the brushed DC motor can operate.

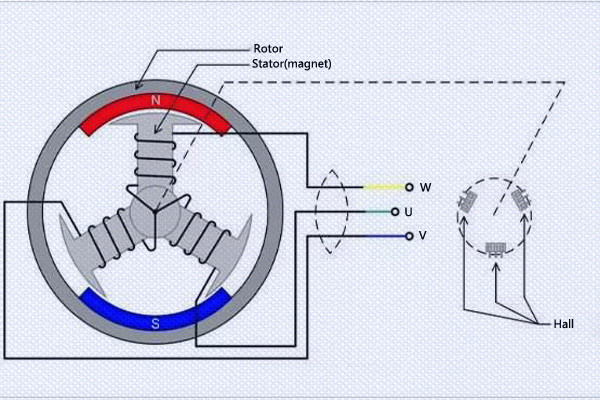

Brushless DC Motor

A Brushless DC Motor (BLDC) is an electric motor powered by a direct current voltage supply and commutated electronically instead of by brushes like in conventional DC motors. BLDC motors are more popular than the conventional DC motors nowadays, but the development of these type of motors has only been possible since the 1960s when semiconductor electronics were developed.

Gearbox Types

Spur Gearbox

Spur gears are used in mechanical applications to increase or decrease the speed of a device or multiply torque by transmitting motion and power from one shaft to another through a series of mated gears.Spur gears are more efficient compared to helical gears with the same size. They are quite reliable and offer constant velocity. Spur gears are also considered a member of positive transmission because they don't have any slippage

Planetary Gearbox

A planetary gearbox is a gearbox with the input shaft and the output shaft aligned. A planetary gearbox is used to transfer the largest torque in the most compact form (known as torque density).Planetary gear systems are able to produce a lot of torque because the load is shared among multiple planet gears. This arrangement also creates more contact surfaces and a larger contact area between the gears than a traditional parallel axis gear system.

Worm Gearbox

Worm gears operate by the friction created by turning lubricated gears. The friction is then converted into heat. By producing a low speed and high-speed torque level, worm gears are utilised as speed reducers, which implies that they are ideal for several applications. In theory, a worm gear is self-locking when the static friction angle is larger than the helix angle of the worm. The static friction angle is described as the angle where the load above will start to move.

Applications

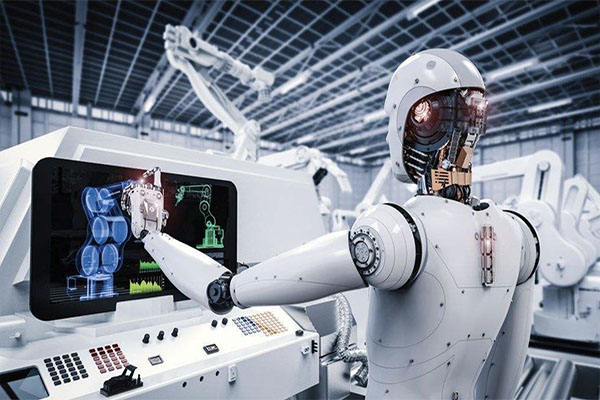

Robotics

From robotic arms to teaching robotics and robotic toys, DC planetary gear motors play a crucial role in facilitating precise and controlled movements.

Sanitary Automations

In dispensers, lid openers, and sensor sanitary bins, DC planetary gear motors contribute to the seamless functioning of sanitary automation systems.

Safe and Security Systems

Electronic locks, door locks, safes, and latch closers benefit from the reliability and efficiency of DC planetary gear motors.

Valve/Meter Mechanisms

Electric valves, gas meters, and water meters leverage DC planetary gear motors for optimal performance.

Curtain Automation

Electric curtains and blinds are enhanced with the controlled and efficient movement provided by DC planetary gear motors.

Coffee Machines

In the realm of coffee machines, including coffee makers and bean grinders, DC planetary gear motors ensure precise and reliable operations.

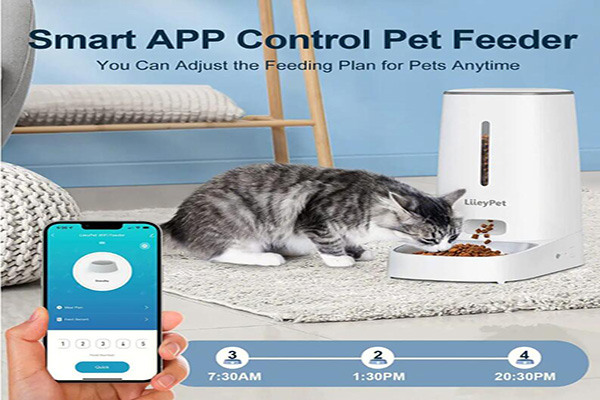

Pet Care Devices

From anti-bark devices to pet feeders and door openers, DC planetary gear motors contribute to the comfort and well-being of our furry friends.

Bank Automation

ATMs, coin counters, coin selectors, coin validators, and banknote counters benefit from the precision and durability of DC planetary gear motors.

Vending Machines

Beverage vending machines, hot and cold drink dispensers, and juicer makers rely on the efficiency and reliability of DC planetary gear motors.

Medical Care Equipment

Diagnostic equipment, medical beds, massagers, and beauty care appliances are empowered by the precision movements of DC planetary gear motors.

Others

From BBQs and 3D printing to baby cradles, fish feeders, humidifiers, and range hoods, DC planetary gear motors find applications in a diverse array of industries and products.

The Ultimate Guide for Planetary Gear Motor

You’re at the right place if you want to learn more about DC Planetary Gear Motors. Look nowhere else! You can learn everything there is to know about DC planetary gear motors in our comprehensive guide. Whether you’re an engineer or a hobbyist, knowing the fundamentals of a DC planet gear motor can be useful for a variety of applications.

Grab some coffee as you learn about how these motors function, how beneficial they are and any drawbacks you should know about. You will also learn how to choose the right one for your application, in this guide. Let’s explore the world of DC planetary gear motors!

What is Planetary Gear Motor?

A direct-current (DC) planetary gear motor is a specific kind of DC motor that features a planetary gear system. A typical DC Motor has the following components: sun gear, a planetary gear carrier, and different planetary gears. Later in this article, you will learn more about how it works.

Some superb features of the DC planetary gear motors is that they have high torque output and exact speed, as well as rotational control. DC motor are available in different sizes, torque ratings and voltage range. This striking feature makes them widely used in smart home, automotive, and robotic applications.

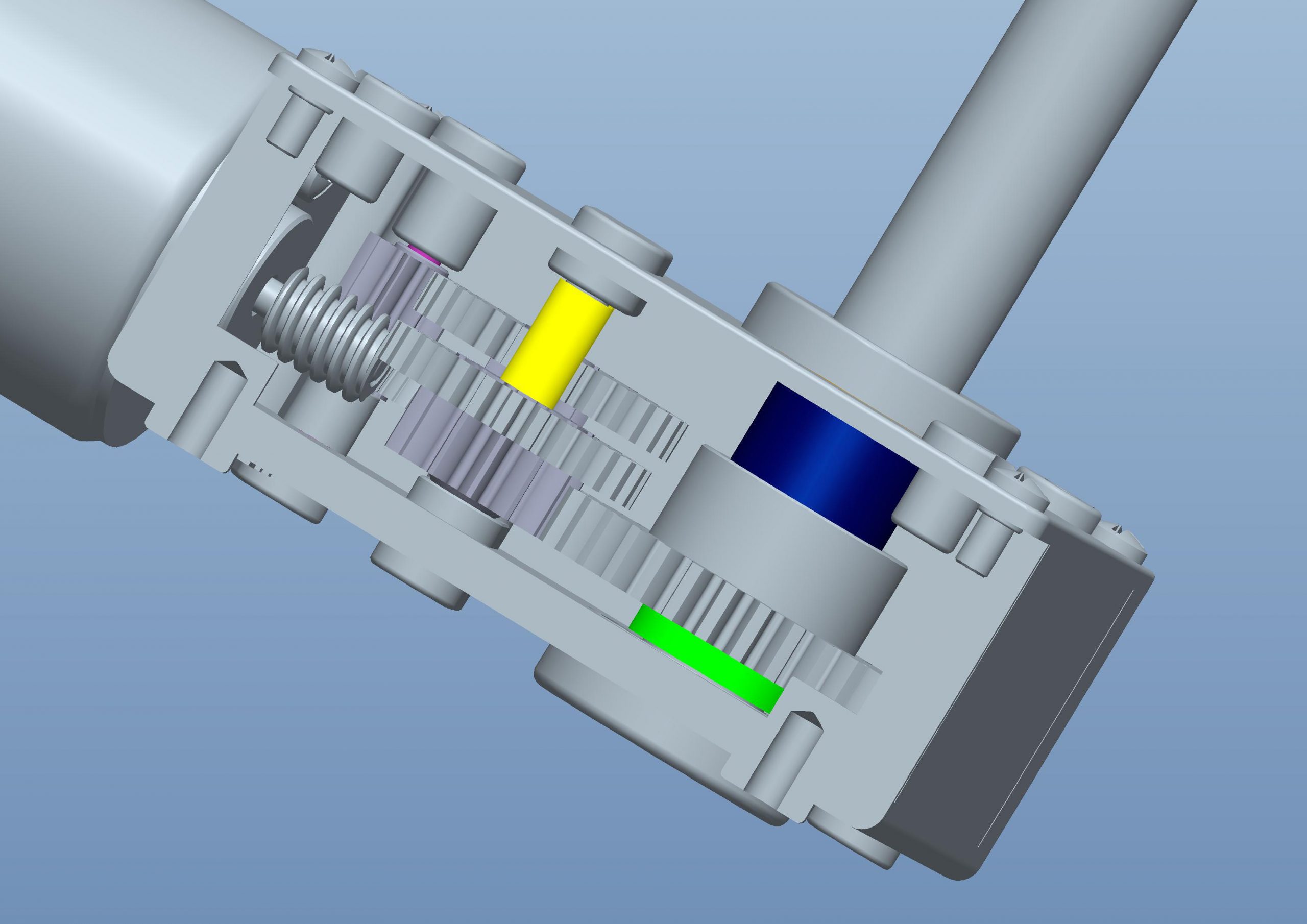

Of all the features of the DC planetary gear motor, also called dc planet gear motor, its compact design, high efficiency, and low noise output are some of its best loved features. These motors are suitable for both low RPM and high RPM applications. In some models, an encoder is built for precise rotation and position control.

There are also different voltage options. Some of these voltage options include: 6V, 12V or 24V planetary gear motors. Trying to figure out which one you need? Well that depends a lot on your application specifications, such as the load capacity and power requirements.

Robotics, automotive, vending machine and medical equipment are a few industries where DC planetary gear motors are frequently used. Power windows, windshield wipers, and seat adjustments are a few of the automotive applications they are used in.

How does the Planetary Gear Motor Works?

The operation of a DC planetary gear motor is quite unusual. Simply put, it transfers rotational motion and torque from the motor shaft to the output shaft using planetary gears. DC motors are built with a main gear which is also called a sun gear. This gear is surrounded by other smaller gears called planetary gears. Do you get the planet and sun idea? We think that’s a pretty cool concept.

Planet gears mesh with the annulus, an outer ring gear, and rotate around the sun gear.

The planet gears’ and sun gears’ teeth counts determine the motor’s gear ratio. The number of teeth on the sun gear divided by the number of teeth on the ring gear is known as the gear ratio. A planetary dc gear motor with a gear ratio of 10:1 will result in one rotation of the output shaft for every ten revolutions of the sun gear, to help you understand. Did that example make things easier to understand?

If you have an application that requires high torque at low speed, then you should definitely pick a DC planetary gear motors — they are perfect for it! These motors are designed with an array of voltage ratings, they are: 6V, 12V, or 24V voltage ratings, 6V planetary gear motor, planetary gear motor 12v, 24v planetary gear motor. They can also produce a lofty amount of torque. To improve the motor efficiency, planetary gear motor with encoder can also be added to help determine the position and speed of the motor. DC motors are quite small and are a great choice for use in applications that have limited space.

What are the Advantages and Disadvantages of Planetary Gear Motor?

Planetary gear motor offer several advantages over other types of motors. Here are some of the advantages:

Advantages:

1. High torque: Looking for DC gear motor renowned for high torque output? Then DC planetary gear motoris you best shot! Since they can deliver high torque in a small size, they are perfect for applications where that is required. Many industries use high torque planetary gear motor.

can deliver high torque in a small size, they are perfect for applications where that is required.

2. Low noise: Planetary gears are suitable for use in applications where low noise is important because their design lowers noise levels. Or it can says the system of planetary dc gear motor has lower noise than other types DC gear motor.

3. Efficiency: The capacity ofdc planetary gear motors to split the load among several gears is the cause of their high efficiency. Due to friction and high temperatures, less energy is consequently lost.

4. Size: Planetary gear motors are the perfect choice for applications where there is a lack of available space due to their compact design. small planetary gear motor has different diameter, like 16mm, 22mm, 24mm, 28mm, 36mm etc.

5. Long lifespan: DC planet gear motor can last longer than other types of motors because of their low friction design.

6. Cost-effectiveness: Due to their efficiency and lengthy lifespan, planetary gear motors have the potential to be more economical than other types of motors.

While there are many good reasons why DC planetary gear motor are the best choice. There are also certain disadvantages you should look out for. Some of the them include:

Disadvantages:

1. Speed range restriction: Due to the way they are designed, planetary gear motors have a restricted speed range. They work best in applications that require low to medium speeds.

2. Limited customization: because of their design, planetary gear motors can be challenging to modify for particular applications.

3. Greater complexity: Planetary gear motors are more complicated than other types of motors because they have more gears and parts.

4. More upkeep: Planetary gear motors may need more upkeep than other types of motors due to their complicated design.

5. Higher price: While planetary gear motors can be more expensive than other types of motors, they can also be more cost-effective in some applications, particularly for larger sizes or custom designs.

How to Select a Suitable DC Planetary Gear Motor?

When selecting a suitable DC planetary gear motor, there are several factors to consider. The following advice will help you choose the ideal DC motor for your requirements:

1. Rated Torque: Your application’s need for torque should be considered as you select the best DC planetary gear motor, so keep that in mind when making your selection. For your application, choose a motor with the right amount of torque.

If you need different rated torque, you can choose DC planetary gear motor according their diameter. It includes 16mm planetary gear motor, 22mm planetary gear motor, 24mm planetary gear motor, 28mm planetary gear motor, 36mm planetary gear motor, 42mm planetary gear motor, 52mm planetary gear motor, 56mm planetary gear motor.

2. Rated Voltage : One thing you cannot ignore when picking a DC motor is knowing what DC motor voltage requirement is best for your application. Depending on your application, you might need any of the 6V, 12V, and 24V DC motors.

3. Gear Motor Speed:Calculate the required motor speed. Different speeds, expressed in RPM, are available for DC planetary gear motors. For example: 300rpm dc planetary gear motor. There are many RPM: 10RPM, 20RPM, 50RPM, 55RPM, 100RPM, 150RPM, 200RPM, etc. Pick a motor that can deliver the speed that is ideal for your application.

4. Size requirements:Make sure the motor can fit in your application by taking into account its physical size. Planetary gear motors come in a variety of sizes, including 36mm, 16mm, 22mm, 24mm, 28mm, 32mm, 42mm, 56mm, etc.

5. Efficiency: These motors’ high efficiency is the result of their ability to distribute the load among several gears. Less energy is consequently lost to friction and high temperatures

6. Encoder: A planetary gear motor with encoder is a good option if your application calls for precise control over the motor’s speed and position. Encoders give the control system feedback, enabling precise management of the motor’s position and speed.

7. Is it brushed or brushless?:Considering whether a brushed or brushless motor is better suited for your application will help you decide which is better. Brushless motors are more expensive but have a longer lifespan than brushed motors, which are typically less expensive but need more maintenance.

8. Manufacturer:Pick a planetary gear motor factory that has a solid track record of creating DC planetary gear motors of high quality. Think about things like the warranty, customer service, and the accessibility of replacement parts.

By taking these things into account, you can choose a DC planetary gear motor that will work for your application.

How to Increase The Lifetime for DC Planetary Gear Motor?

To make your DC Planetary Motor last long for you, here is what you should do.

- Select High-quality gear components: Go for gears made of strong, long-lasting materials. High-quality gears have a longer lifespan for the DC planetary gear motor because they are less likely to wear out and can support heavier loads.

- Store and Transport With Appropriate Materials: Use appropriate packaging materials, such as cartons, to transport or store the DC planetary gear motors to prevent any physical damage that might affect its performance or lifespan.

- Use a Low-speed DC motor: Running the motor at lower speeds can help the gears last longer by reducing stress and wear. It makes DC planetary gear motor has longer lifespan. Select a motor with a lower speed rating if the application permits it.

- Grease Properly:

Make sure to lubricate properly with high-quality grease to prevent friction and gear wear. To ensure ideal lubrication and increase the motor’s lifespan, use the high-quality grease that the manufacturer suggests. Good grease reduces gear wear and make gear having longer lifespan for planetary gear motor.

- Select a Low Gear Ratio:

Lower gear ratio means using less gears. The load torque is smaller. The gear’s load is small, you can lessen wear and increase the DC planetary gear motor’s overall lifespan.

- Don’t Bend the Rules:

Follow the planetary gear motor manufacturer recommended operating guidelines. Avoid going over the voltage, current, or torque limits because doing so can make the planetary gear motors gear broken, or make motor short circuit.

How To Reduce The Noise Of Planetary Gear Motor?

Reducing the noise of your Planetary Gear Motor is important. No one wants a noisy device anyway. Here are some things you should look out for if you want to reduce the noisiness of your 6V planetary gear motor, 12V planetary gear motor, or 24V planetary gear motor:

Low-speed DC Motors Are Your Go-to Option: DC motors with low rotational speeds are the best option for reducing operating noise. Because high-speed rotations typically make more noise, lower speeds frequently result in quieter motor operation. Low RPM DC motor makes planetary gear motors has lower noise.

- Make use of good-quality grease: Using Proper lubrication is essentialto reduce noise for gear and gearbox. Pick a grease of excellent quality that is made especially for use in gear applications. Smoother and quieter operation is achieved by reducing friction and noise brought on by gear meshing with the help of good grease. The DC planetary gear motor’s gearbox structure is great at keeping grease inside planetary gearbox.

- Plastic Gears Are The Best For The First Stage: On the first stage of planetary gear motor’s gearbox, it can use plastic gear. Noise levels can be greatly influenced by the material used for gears. Given that they tend to produce less vibration and quieter operation than metal gears, plastic gears, particularly in the first stage of the gear system, can help reduce nois

- Choose gears made of special materials that reduce noise: Some gear manufacturers sell specially engineered noise-reduction gears that are made of unique materials. These materials frequently have improved damping properties, which lower operating gear noise.

How To Increase the Torque Of Planetary Gear Motor?

A planetary gear motor can operate more effectively in a variety of applications, perform better, and handle heavier loads if DC planetary gear motor torque output is increased. Here are some ways to increase the planetary DC gear motor torque output:

Select a Bigger DC Motor:

choosing a motor with more torque and bigger physical dimensions for the planetary gear motors. A larger motor typically produces higher torque, giving a firmer foundation for increased torque output. Like 50mm dia 775 DC motor, 56mm dia DC motor, etc

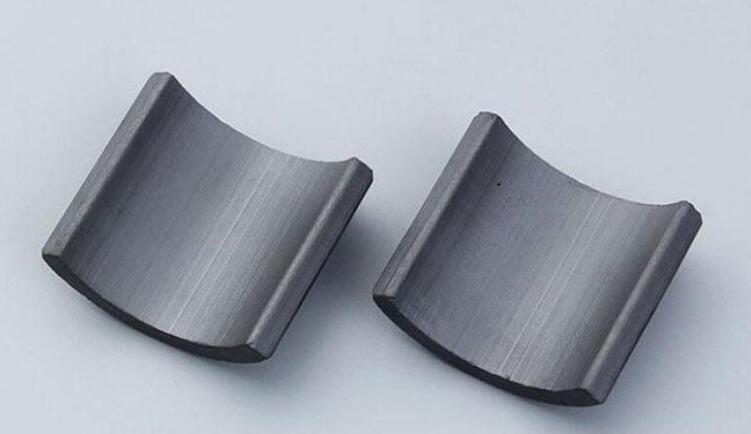

Consider Upgrading The Magnet Configuration:

This can be achieved by using stronger magnetic tiles or by investigating different magnet materials, such as neodymium magnets. Magnetic tile is more powerful than Rubber magnetic strip. The motor’s ability to produce torque is improved by optimizing the magnetic configuration. And the output rated torque is higher for DC planet gear motor.

Improve The Gear Ratio:

Change the gear ratio to produce more torque for high torque planetary gear motor. To increase torque multiplication, the gear ratio must be raised, which entails having more teeth on the output gear in comparison to the input gear. More gears are used in gearbox of planetary gear motor. This raises the torque at the output shaft.

Make Use Of a Multiple-stage Planetary Gearing System:

If you want higher torque for DC planetary gear motors, To increase torque output even more, add additional stages to the planetary gear system. The torque capability increases overall with each stage’s addition of torque multiplication. Systems with multiple stages of gearing are particularly good at producing a lot of torque.

What Affects the Efficiency of Planetary Gear Motor?

If you want higher torque for DC planetary gear motors, To increase torque output even more, add additional stages to the planetary gear system. The torque capability increases overall with each stage’s addition of torque multiplication. Systems with multiple stages of gearing are particularly good at producing a lot of torque.

- The efficiency of the Gear System: Why planetary gear motor has high efficiency? Because of it’s special planetary gearbox system.The motor’s internal gear system efficiency has a big impact on overall efficiency. The frictional losses and effectiveness of power transmission are influenced by elements like gear material, gear tooth profile, and lubrication.

- Motor Performance: The DC motor’s performance is extremely importantfor planetary gear motors. Different motor types, like brushless DC motor or brushed DC motor, have different efficiency traits. The effectiveness of a motor can be impacted by elements such as its size, winding design, and component quality. Using brushless DC motor is a good option to obtain high efficiency for planetary dc gear motor.

- The Gear Ratio Used: The efficiency of a motor can be impacted by mechanical losses, such as bearing friction, seal drag, and windage losses. The efficiency of the motor can be increased by reducing these losses through proper lubrication, bearing selection, and efficient design.

- Mechanical Losses:The efficiency of a motor can be impacted by mechanical losses, such as bearing friction, seal drag, and windage losses. The efficiency of the motor can be increased by reducing these losses through proper lubrication, bearing selection, and efficient design.

Why Planetary Gear Motor Lifespan is Longer than Other DC Gear Motor?

Due to several factors, planetary gear motors typically have longer lifespans than other types of DC gear motors. The most important factor is planetary gear motor’s special planetary gearbox system.

The planetary gear structure distributes the load among several gears, resulting in less wear and a longer gear tooth life. The motor can withstand heavy loads, vibrations, and shocks thanks to its compact and sturdy design and use of high-quality materials.

The special planetary gearbox keep the grease inside gearbox. It makes gear lubricating continuously. Longer lifespans are facilitated by efficient lubrication systems and maintenance procedures that guarantee proper lubrication and reduce friction. Planetary gear systems’ longevity is also increased by the effective control of torque distribution, axial loads, and damping characteristics.