Brushless Gear Motor Factory: How it works and what are advantages?

Brushless gear motor is a brushless DC motor with gearbox – a motor without brushes, commutators, and the friction that comes with them. Electromagnetic induction takes center stage, where an electric current sets the stage for a magnetic field. Brushless gear motor has many advantages: High Efficiency, compact design, precise control, High Torque, Low maintenance. Brushless gear motor applications: smart robotics, precise medical, smart home, etc.

Introduction:

Step into the fascinating world where gears meet innovation, and motors redefine precision – welcome to the realm of brushless gear motor. In a landscape pulsating with technological advancements, these motors emerge as the undisputed powerhouse, seamlessly blending power, efficiency, and compact design. As industries evolve, demanding more than ever before, brushless gear motor takes center stage. In this gripping guide, we embark on a journey to unravel the mysteries behind their construction, working principles, performance advantages, and applications, and even pit them against their counterpart – the Brushless DC Motor.

1. Brushless DC Gear Motor Construction and Systems:

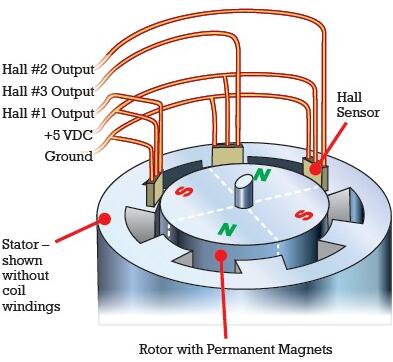

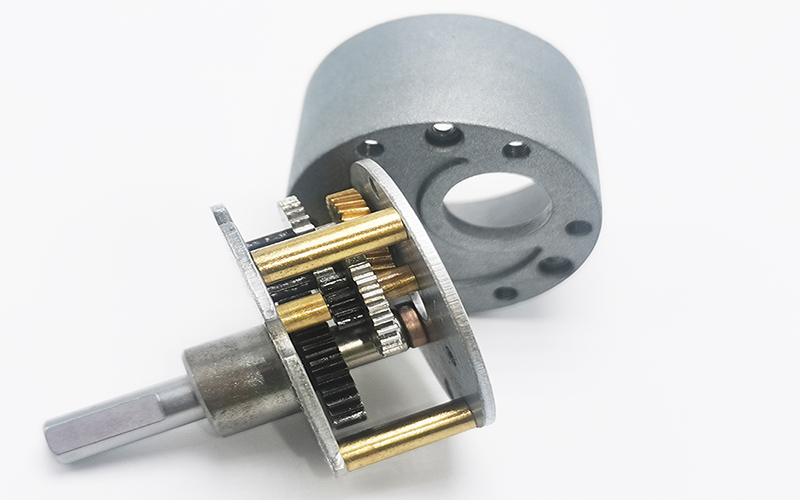

Picture this: a motor without brushes, commutators, and the friction that comes with them. That’s the world of brushless DC gear motor – a world where innovation eradicates obstacles. Internally, a dance between rotor and stator takes place, magnets in the rotor orchestrating a silent symphony of electronic power transfer. No physical contact, just pure efficiency, and durability. Now, throw in a gearbox, and suddenly you’ve got a motor ready to conquer applications demanding both precision and brute force.

2. Brushless Gear Motor Working Principles:

Electromagnetic induction takes center stage, where an electric current sets the stage for a magnetic field. The rotor, like a performer on cue, starts its magnetic dance. Here’s the twist – no brushes needed. Electronic controllers waltz in, orchestrating the commutation process with the finesse of a maestro. Brushless gear motor has bldc gear motor 12V and bldc gear motor 24v. You can use 12V or 24V.

The result? Smoother, more precise motor control. Now, attach a gearbox, and you’ve got a showstopper – a motor ready to take on tasks with finesse and flair across industries.

3. Performance Characteristics (Advantages):

The stage is set; it’s time for the performance. BLDC gear motor take a bow, showcasing performance characteristics that make them the darlings of various applications.

- High Efficiency: Imagine a motor with no friction – that’s the efficiency we’re talking about. Less wear and tear, more performance, and a lifespan that just keeps going.

- Compact Design: Size matters, especially in a world where space is a premium. Compact and lightweight, these motors waltz into tight spots with ease, thanks to the integrated gearbox enhancing BLDC gear motor power density.

- Precise Control: Ever witnessed a motor execute intricate maneuvers with the precision of a surgeon’s scalpel? That’s electronic commutation at its finest, providing precise control over speed and direction.

- High Torque: Need power at low speeds? Enter the gearbox, turning these motors into torque giants, perfect for applications where starting torque is not just an option but a necessity.

- Low Maintenance: Less wear means less maintenance. Fewer components prone to wear and tear translate into significant cost savings over the lifespan of these BLDC gear motor.

4. Application:

In various industries, brushless DC gear motor play a crucial role due to their versatility, precision, and power. In robotics, these motors handle intricate movements for tasks like surgical procedures and manufacturing operations, seamlessly integrating into confined structures. In medical devices, geared brushless motor elevate surgical precision and manage diagnostic equipment with reliability. Automation systems rely on them to power conveyor systems and packaging machinery, ensuring efficient and precise automated production. Industrial machinery benefits from these geared brushless motor in machine tools for tasks like milling and drilling, as well as in material handling equipment for robust performance. In aerospace and defense, brushless DC gear motor contributes to the efficiency of unmanned aerial vehicles (UAVs) and guide missile systems with precision. In renewable energy applications, they maximize solar energy absorption in solar tracking systems and contribute to wind energy conversion in wind turbines. Finally, in automotive systems, these geared brushless motor power automated doors and windows and provide precision control for seat adjustments, enhancing overall vehicle automation and comfort for both engineers and laypeople.

5. Differences between Brushless Gear Motor and Brushless DC Motor

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Gearbox Integration

The Brushless Gear Motor takes center stage with its symphony of gears, integrating a gearbox for torque multiplication and speed reduction. On the other hand, the Brushless DC Motor performs a solo act, typically without an integrated gearbox, embracing simplicity in design.

Precision vs. Simplicity

In the precision department, the Brushless Gear Motor shines as a precision dancer, tailored for applications demanding accuracy. Meanwhile, the Brushless DC Motor, known for simplicity, proves a versatile performer suitable for less precision-centric applications.

Torque Output

When it comes to torque, the Brushless Gear Motor is the powerhouse, delivering high torque, especially at lower speeds. The Brushless DC Motor, while capable, lacks the high torque output of geared systems.

Application Focus

The Brushless Gear Motor takes the lead in applications requiring high torque, precision control, and a compact design – the triple threat. In contrast, the Brushless DC Motor serves as the versatile understudy, ideal for simpler applications where efficiency and moderate torque are the stars.

Efficiency and Maintenance

The brushless dc gear motor 12v presents a complex drama with the gearbox introducing mechanical losses. However, the reduction in wear and tear compensates for lower maintenance requirements. On the other hand, the Brushless DC Motor keeps it straightforward, with simplicity enhancing overall efficiency but potentially requiring more frequent maintenance.

Cost Considerations

The captivating show of the brushless dc gearmotor may come with a higher upfront cost due to the gearbox. Still, the promise of long-term benefits and reduced maintenance costs steals the spotlight. In contrast, the Brushless DC Motor provides an economical start, winning hearts with simplicity, but ongoing maintenance costs may play a role in the overall drama.

Versatility

The Brushless Gear Motor plays the role of a chameleon, enhancing versatility with its integrated gearbox, allowing for customization of speed and torque characteristics. On the flip side, the Brushless DC Motor acts as the adaptable generalist, versatile but with simplicity potentially limiting customization options.

Comparison Table

Feature | Brushless Gear Motor | Brushless DC Motor |

Gearbox Integration | Integrated gearbox for torque and speed control | Typically lacks an integrated gearbox, embracing simplicity |

Precision vs. Simplicity | Precision-oriented for accuracy | Versatile performer in less precision-centric applications |

Torque Output | High torque, especially at lower speeds | Capable but lacks the high torque output of geared systems |

Application Focus | High torque, precision control, and compact design | Suitable for simpler applications with moderate torque |

Efficiency and Maintenance | Complex with potential mechanical losses; lower maintenance | Straightforward, efficient, but may require more frequent maintenance |

Cost Considerations | Potentially higher upfront cost with long-term benefits | Economical upfront, ongoing maintenance costs may impact overall cost |

Versatility | Enhances versatility with integrated gearbox | Adaptable but simplicity may limit customization options |

In wrapping up our exploration of brushless gear motors, it’s evident that these machines aren’t just pieces of equipment; they’re the driving force behind innovation. From their structure and principles to their performance advantages and applications, they emerge as the unsung heroes propelling us into the future. In a world where precision meets power and efficiency partners with versatility, brushless gear motors stand tall, poised to script the next chapter in modern engineering possibilities. Whether you’re fascinated by robotics or interested in industrial machinery, one thing is certain – the future runs on the relentless innovation of brushless gear motors.