12V Worm Gear Motor

What is 12V Worm Gear Motor with Dual Shafts?

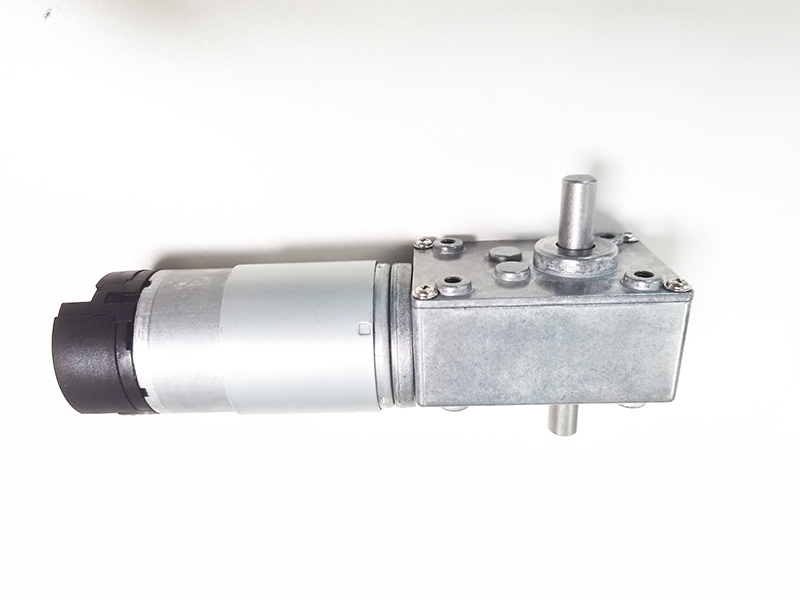

A 12V worm gear motor with dual-shaft , sometimes called a double shaft worm gear motor or a dual shaft DC gear motor, is a specialized type of electric motor designed for applications requiring dual output shafts. This motor features two parallel output shafts extending from both ends of the motor housing, providing versatility in mechanical connections and applications. A dual shaft 12V worm gear motor is an electric motor with two output shafts extending from opposite ends of the motor housing. These shafts allow the motor to transmit mechanical power in two directions simultaneously.

The main advantage of a dual shaft 12V worm gear motor is its ability to drive multiple mechanisms simultaneously or perform various tasks within a single device. This design allows for the transmission of power and motion to two different components, making it useful when space and weight constraints limit the use of multiple motors.

What Kind of DC Worm Gear Motor we have?

DC Worm Gear Motor

Gearbox Width: 9*20mm

Voltage: 3V~12VDC

Speed: 2RPM~250RPM

Torque: 0.1kg.cm~5kg.cm

DC Worm Gear Motor

Gearbox Size: 32*46mm

Voltage: 6V~24VDC

Speed: 2RPM~250RPM

Torque: 1kg.cm~27kg.cm

DC Worm Gear Motor

Gearbox Size: 32*46mm

Voltage: 6V~24VDC

Speed: 2RPM~250RPM

Torque: 1kg.cm~30kg.cm

Worm Gear Motor

Gearbox Size: 40.1*58mm

Voltage: 12V~24VDC

Speed: 2RPM~120RPM

Torque: 0.6kg.cm~30kg.cm

DC Worm Gear Motor

Gearbox Size: 40.1*58mm

Voltage: 12V~24VDC

Speed: 2RPM~122RPM

Torque: 1kg.cm~80kg.cm

DC Worm Gear Motor

Gearbox Size: 50*75mm

Voltage: 12V~24VDC

Speed: 2RPM~50RPM

Torque: 0.5kg.cm~70kg.cm

DC Worm Gear Electric Motor

Gearbox Size: 50*75mm

Voltage: 12V~24VDC

Speed: 2RPM~50RPM

Torque: 0.5kg.cm~70kg.cm

DONGMING worm gear motor has many benefits:

- High torque in rated load

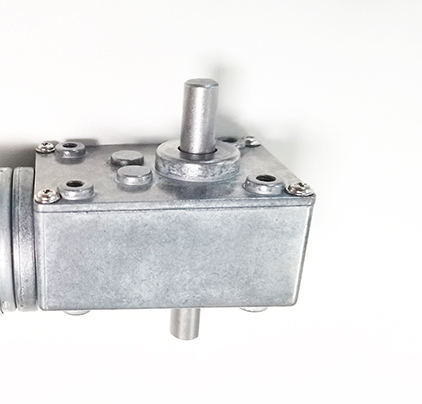

- 90° degree, right angle output shaft

- Can be double output shaft

- Self-lock for output shaft

- High Static torque

- Low noise

- Stable transmission

- Stable structure

DONGMING MOTOR provide customized parameter, spcification, and provide best and suitable performance for your project. These points are we focus on:

- DC Motor Type: Brushed DC motor/ Brushless DC motor

- Gearbox Type

- Operating Voltage

- Output Rated Speed

- Rated Torque

- Stall Torque

- Static Torque

- Output Power

- Load Current

- Stall Current

- Gear Material

- Encoder

- Lifespan

- Noise Level

- Output Shaft Length, Customized Spec

- Reduction Ratio for Gearbox

- Shaft Configuration: (D Cut / Round / Splined / Other)

- Overall Size Parameters (L, W, H)

- Sweeping Robot

- Range Hood

- Tennis ball Launcher

- Electric Valve

- Automatic Cooking

- Electric Blinds/Curtian

- Coffee Maker Motor

- Electric Standing Desk

- Medical

- Smart Homeetc

These motors are commonly used in robotics, automation, conveyor systems, and other industrial applications requiring precise control and coordination of multiple moving parts. The gear mechanism, particularly the worm gear, helps reduce the motor’s speed while increasing torque, making it suitable for high and low-speed operation tasks.

Here’s a breakdown of the key components and characteristics of a dual-shaft 12V worm gear motor:

DC Motor

The motor is typically a 12V DC motor, which means it operates on a 12-volt power supply. DC motors are commonly used for applications requiring variable speed and precise control.

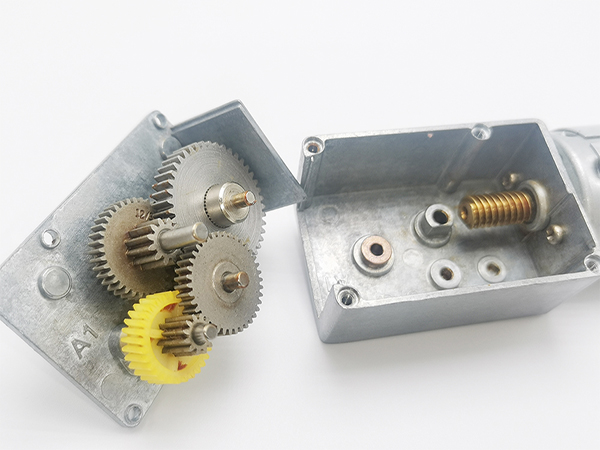

Worm Gear

The worm gear is a specific type of gear mechanism used in this motor. It consists of a screw-like component (the worm) that engages with a toothed wheel (the worm gear). This arrangement allows for a high gear reduction ratio, which means the motor can provide high torque at low speeds.

Dual Shafts

The motor has two output shafts, one on each side of the housing. These shafts are extensions of the motor's output and rotate in response to the motor's operation. The dual shaft design provides versatility, allowing for the simultaneous use of both shafts to power different mechanisms or perform multiple functions.

A double shaft worm gear motor is a specialized electric motor with two output shafts. It makes it versatile and valuable in various applications, particularly those that demand the synchronization of multiple components or systems. Applications for dual shaft 12V worm gear motors can vary widely, as they are often used when precise control, bidirectional motion, and high torque at low speeds are required. Typical applications include robotics, conveyor systems, automation equipment, and any other scenario where a motor needs to drive multiple components or perform tasks in two directions.

A worm gear motor 12V with dual shafts, often called a double shaft worm gear motor or dual shaft DC gear motor, operates with two output shafts extending from the motor. This design offers versatility and flexibility in various applications requiring precise control and multiple outputs.

The core principle behind the functioning of this motor involves a worm gear mechanism. At its heart, there is a worm gear, a screw-like component, which is typically driven by an electric motor. The worm gear meshes with a worm wheel, a flat, disk-like gear with teeth. As the worm gear rotates, it engages with the worm wheel, causing it to turn.

The motor can simultaneously transmit rotational motion to two separate output shafts with dual shafts. This is particularly useful when driving multiple components or performing different functions with a single motor. Each output shaft can be independently connected to various mechanisms, devices, or equipment, allowing for precise control and synchronization of multiple processes.

The dual shaft design ensures that the motor’s torque and power are distributed evenly between the two output shafts, making it suitable for applications that require balanced performance. This can include conveyor systems, robotics, automated machinery, and more.

In summary, a 12V worm gear motor with dual shafts functions by using a worm gear mechanism to drive two separate output shafts simultaneously. This design provides versatility and precise control, making it suitable for various applications requiring dual outputs.

What worm gear's materials for the 12V worm gear motor?

Choosing materials for the worm gear in a 12V worm gear motor is crucial, as it directly impacts the motor’s performance, lifespan, durability, and efficiency. Worm gears are typically made from various materials, offering specific advantages and limitations. Common materials for worm gears include:

Steel

Steel is a popular choice due to its strength and durability. It can handle heavy loads and high-torque applications, making it suitable for industrial and heavy-duty applications. Steel worm gears can be further categorized into carbon steel and alloy steel, with alloy steel providing better resistance to wear and corrosion.

Bronze

Bronze worm gears are known for their self-lubricating properties, which reduce friction and wear. They are often used in applications where quiet operation and minimal maintenance are essential, such as automotive steering systems and small-scale machinery.

Plastic

Plastic worm gears, typically made from materials like nylon or Delrin (acetal), are lightweight and cost-effective. They are often used in applications where noise reduction, non-corrosiveness, and ease of fabrication are critical. However, they may not be as durable as metal worm gears and are better suited for lower torque and less demanding applications.

Stainless Steel

Stainless steel worm gears are corrosion-resistant and offer good strength. They are commonly used in applications where exposure to moisture or corrosive environments is a concern. However, they may not be as strong as carbon or alloy steel.

The choice of material depends on various factors, including the specific application, required load capacity, operating environment, and budget. It’s essential to consider the trade-offs between factors like strength, cost, corrosion resistance, and self-lubricating properties when selecting the appropriate material for the worm gear in a 12v dc right angle gear motor. Additionally, the choice of material may vary among manufacturers and models, so it’s advisable to consult the motor’s specifications and guidelines provided by the manufacturer for the best results.

Add Your Heading Text Here

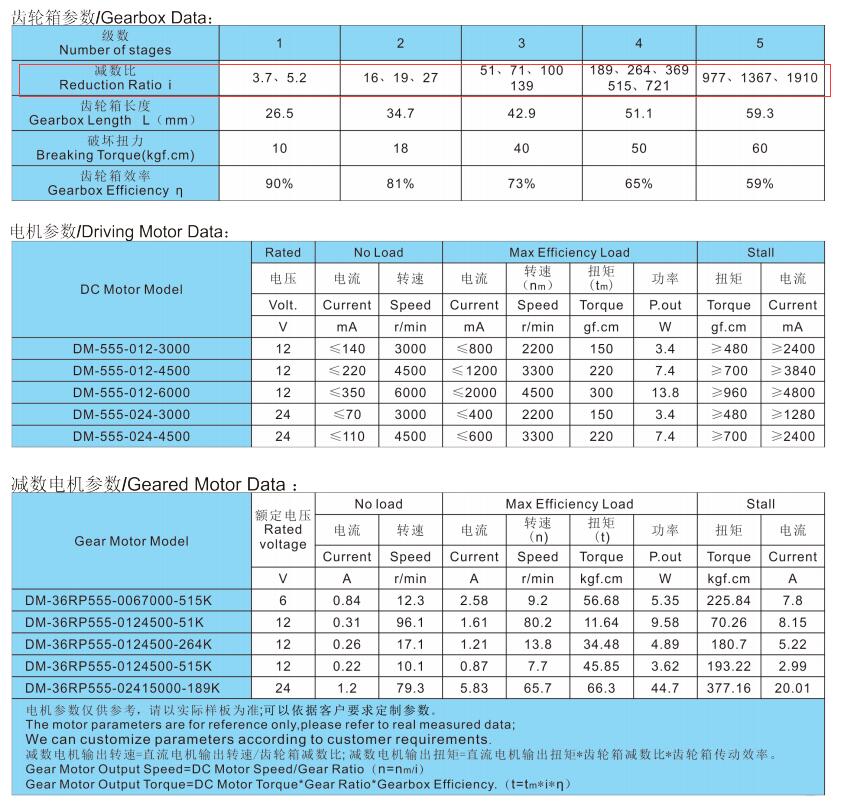

You can employ a simple yet effective technique involving gears to reduce the RPM of your 12V worm gear motor. 12 volt dc worm gear motor called 12V dc right angle gear motor. Begin by selecting a suitable gear ratio, depending on your specific requirements. Determine the initial RPM of your motor and the target RPM you desire.

Calculation example:

DC Motor: no load 6000RPM

Ratio: 1: 100

So The output speed of DC gear motor is 6000÷100=60RPM.

The no load output speed is 60rpm for 12 Volt worm gear motor. Please check the following data-sheets, and you can calculate it by yourself.

When working with 12 volt worm gear motor, achieving the desired output speed and torque requires gear reduction. Gear reduction involves reducing the motor’s rotational speed while increasing its torque. This is achieved by employing gears with different numbers of teeth, resulting in a gear ratio greater than 1:1. For instance, if the DC motor speed is at 5000 RPM and you want to slow it down to 50 RPM, you’ll need a 100:1 reduction ratio. Once you have the ratio figured out, it’s time to calculate the sizes of the gears you’ll use. You’ll need a smaller gear (the pinion gear) that attaches securely to the motor’s output shaft and a larger gear (the driven gear) that connects to the output shaft of your gearbox.

With your gear sizes calculated, construct the gearbox housing. It’s essential that this housing is robust and well-aligned to minimize friction and wear over time. The gearbox will not only hold the gears but also support the motor and output shaft. The next step involves connecting your motor and gears. Secure the pinion gear to the output shaft of your 12V worm gear motor, ensuring it meshes correctly with the driven gear inside the gearbox.

Now comes the critical testing phase. You want to ensure that the output RPM aligns with your desired reduction ratio. In case the RPM is not where you want it to be, you can fine-tune the gear sizes or replace gears as needed. This testing and adjustment phase ensures your setup performs precisely as required.

Pay attention to sealing and lubrication to enhance your gear system’s longevity and efficiency. Ensure the gearbox is appropriately sealed to prevent dust and debris from entering, which can cause premature wear and damage. Properly lubricating the gears reduces friction, minimizing wear and maximizing the lifespan of your setup.

Finally, mount the entire assembly in your application, considering any specific positioning and alignment requirements. By following these steps and using the proper gear ratio and gear selection, you can effectively reduce the RPM of your 12 volt dc worm gear motor, allowing you to tailor its performance to your precise needs. The gearbox serves as a reliable speed reducer, giving you the ability to control the motor’s output speed while maintaining its essential torque characteristics, ensuring your system operates smoothly and efficiently.