Planetary Gear Motor 12V

How to Boost the Power: Increasing the Output Torque of Planetary Gear Motor 12V

When it comes to enhancing the performance of a 12V Planetary Gear Motor, the key lies in increasing the output torque. This crucial aspect is pivotal for heavy-duty applications, demanding precision machinery, and seamless automation processes. In this comprehensive guide, we’ll unravel the strategic approaches to boost the power of a 12V Planetary Gear Motor, ensuring it operates at its full potential.

Increase DC Motor Speed: Unleashing Rapid Precision

The first strategy involves increasing the speed of the DC motor. By ramping up the motor speed, the planetary gear system accelerates, resulting in a proportional increase in torque output. This strategic approach is particularly effective when swift and precise movements are required in applications such as robotics, where responsiveness is paramount.

Using Ferrite for DC Motor’s Magnet: Elevating Magnetic Efficiency

The choice of magnet material in the DC motor plays a critical role in determining its performance. Utilizing ferrite magnets enhances the magnetic efficiency of the motor, contributing to a more powerful and efficient operation. This strategic adjustment is especially beneficial when seeking to maximize torque output without compromising energy efficiency.

Increase Ratio: Introducing More Stages for Optimal Gearing

Increasing the gear ratio within the planetary gear system is another strategic move. This involves incorporating more stages of gears, allowing for a higher reduction ratio. This step-by-step gearing amplifies torque output, making the Planetary Gear Motor 12V suitable for applications requiring substantial force and power.

Using Bigger DC Motor: Amplifying Motor Muscle

A straightforward approach to enhancing torque is opting for a bigger DC motor. A larger motor inherently possesses more power and capability, directly translating to increased torque output for Planetary Gear Motor 12V. This strategy is advantageous in scenarios where the application demands higher force and endurance, making it a go-to solution for heavy-duty industrial applications.

Using Bigger Planetary Gear Motor 12V: Synergizing Power and Gearbox Size

For a comprehensive boost in torque, consider not only a larger DC motor but also a bigger Planetary Gear Motor 12V. This involves an upgrade to both the motor and the gearbox, ensuring a harmonious synergy between the power source and the gearing system. This strategic combination caters to applications requiring a significant increase in torque without compromising on efficiency.

Conclusion: Gear Up for Unmatched Performance

In conclusion, unlocking the full potential of a Planetary Gear Motor 12V involves strategic adjustments tailored to the specific requirements of the application. Whether it’s accelerating the motor speed, optimizing magnetic efficiency, increasing gear stages, upgrading to a larger DC motor, or synergizing with a bigger Planetary Gear Motor 12V, each approach contributes to a significant boost in torque output.

Now is the time to gear up for unmatched performance. Elevate your machinery’s capabilities by implementing these strategic approaches. Upgrade your Planetary Gear Motor 12V today and witness the transformative power it brings to your applications.

“Dive into the world of torque marvels with planetary gear motor 12V. Discover why their structural prowess, precise alignment, and operational efficiency make them the unbeatable choice for heavy-duty applications. Upgrade now for superior torque and elevate your machinery’s performance to new heights!”

Why Planetary gear motor 12V has higher torque than other gear motor

In the realm of gear technology, the planetary gear motor 12V emerges as a torque marvel, outperforming other gear motors through a series of unique characteristics. Let’s delve into the listing and detailed explanation of the factors that give planetary gear motor 12V the upper hand:

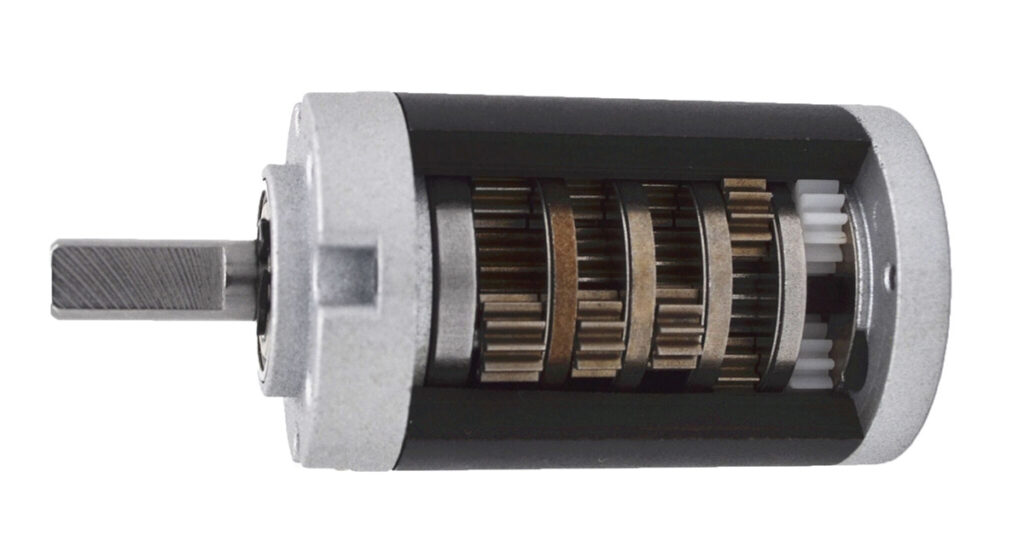

1. Planetary Gearboxes: A Structural Powerhouse

- Planetary gearboxes has inherent strength, eliminating the need for a separate transmission shaft or flywheel.

- Unlike spur gears, which rely on friction reduction, planetary gears operate with a wider angle of revolution, providing enhanced freedom and flexibility. This structural advantage of planetary gear motor 12V contributes to their superior strength and adaptability.

2. Gear Alignment: Precision in Motion

- Planetary gears are aligned in parallel planes, offering a distinct advantage in terms of torque output.

- The alignment of planetary gears allows for varied speeds and directions of rotation, resulting in increased torque. This configuration sets them apart from spur gears, contributing to their unmatched performance in heavy-duty applications.

3. Planetary Gearbox Shape: A Load Torque Boost

- The characteristic design of a planetary gearbox grants it higher load torque compared to helical gears. The specific shape of planetary gears, featuring a wider angle of revolution and an extended tooth profile, enhances their load-bearing capabilities. This makes planetary gearboxes particularly adept at handling heavy loads, positioning them as a preferred choice in certain applications.

4. Efficiency at its Core: A Gear Meshing Advantage

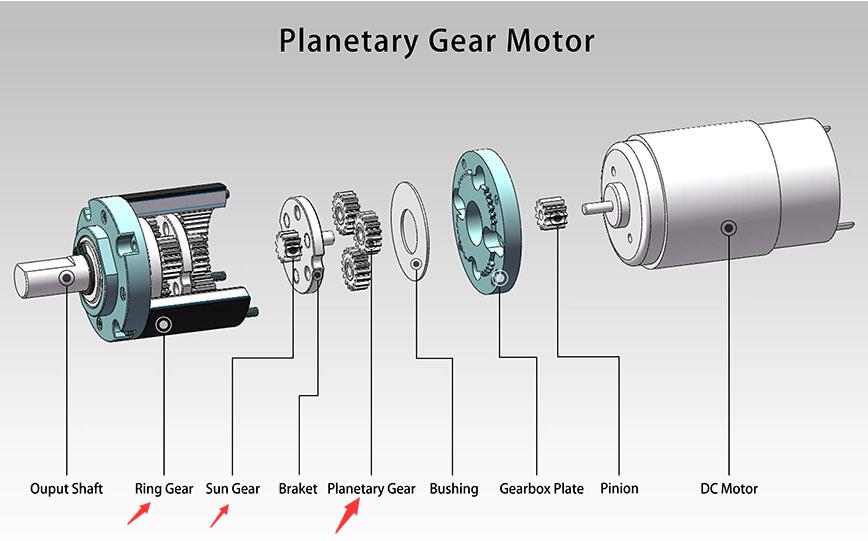

- The gear meshing in planetary systems results in higher efficiency. No helical gear. It is one sun gear in central, three planet gear surrounded by this sun gear, The outermost circle is the ring gears. Please check the planetary gear motor 12V exploded view

- The efficiency gains in planetary gear systems are attributed to their precise meshing, ensuring optimal power transmission. This advantage makes planetary gear motor 12V ideal for applications where efficiency is paramount.

5. Reduced Noise and Vibration: A Quieter Operation

- Planetary gear motor 12V tends to produce less noise and vibration during operation, creating a quieter working environment.

- The design of planetary gear systems minimizes friction and ensures smooth operation, leading to reduced noise and vibration levels. This characteristic enhances the overall user experience and contributes to a quieter industrial setting.

Conclusion: Elevate Your Machinery with Planetary Gear Motor 12V

In conclusion, the planetary gear motor 12V stands as a torque powerhouse, leveraging its unique characteristics to outshine other gear motors. The structural advantages of planetary gearboxes, precision gear alignment, load torque optimization, and operational efficiency collectively make these motors an unparalleled choice for heavy-duty applications.

As you consider the special planetary gear system, the reasons behind the superior torque of planetary gear motor 12V become evident. Upgrade your machinery today and experience the transformative power of planetary gear motor 12V. Gear up for efficiency, precision, and unmatched torque—take the lead in your industry with the torque marvel that is the planetary gear motor 12V.