DONGMING R&D Team

Provide customers with transmission design,mold manufacturing,parts production and assembly services.

What can we do for your projects?

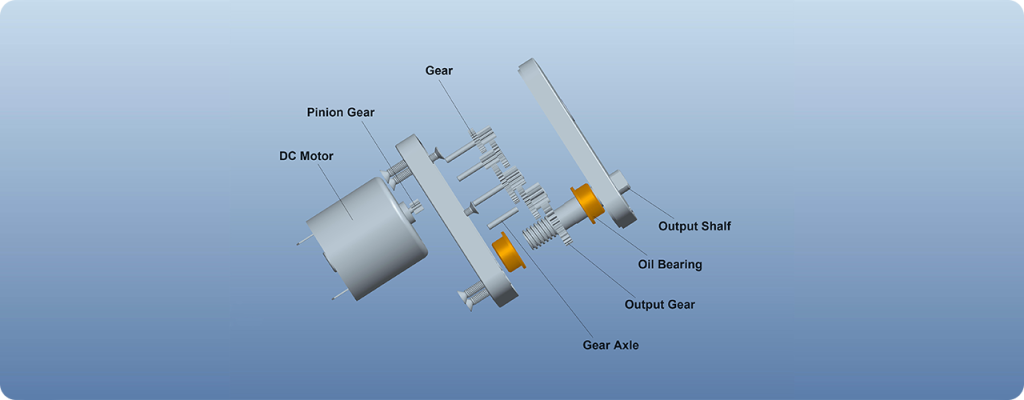

Operation Guide Of DC Gear Motor

Installation

The standard fasten direction is to set the shaft in horizontal direction, to change the direction may cause the oil leaking, and also cause the load direction changing, this may influence the motor performance and lifetime.

Shaft Machine

Do not machine the motor shaft without getting information from us, this may cause the damage of gear and gears cooperation.

Run the shaft(DC Gear Motor)

Do not turn the shaft by hand when adjust the install direction, this will turn the gearbox to be an increaser not a reducer, and also this will turn the Dc Motor to be Generator.

Terminal Welding

When welding the terminal with wires, please use the Iron temperature at 350~400°C within 2-3 seconds. Too high temperature or too long time will cause damage to motor terminal and connection parts, especially when it is metal Brushed motor.

Stall or overload

The Winding and Iron will create heat during motor running, and this heating will gradually increase, under normal load, the temperature can be balance between creating and releasing, it will not burn the motor winding. But if often use the Stall or Overload, the temperature can not be balance as normal, it will gradually burn the Resistant Layer over the Winding, then cause the winding to be burnt down.

Low Speed running

For Carton Brushed Motor, during the working of motor, the carbon Brush will be gradually wore off, and the carbon Powder will be rub off the brush. So if the motor is in lower speed, the carbon power will accumulate in the Commutator slots, when the quantity increases, it will cause the motor to be short circuit. To avoid this situation, we use different kinds of technics and materials according to different motor and speed, so it is very important that users let us know their working voltage of the motor.

Noise Solution

When you have strict requirements on noise and Electromagnetic Interference, please inform us in advance, we have ways to handle these issues.

Inertia and Solution

When the power is cut off, the motor will continue to run for a few seconds, we call this Motor Phenomenon. All the DC Motors have such Phenomenon. If you want solve this issue, you just need to connect the motor “+” to “-“, then this phenomenon will disappear. This is to use Motor-Generator Features(Inverse Current), however this action will cause a high momentary current, usually perform this action will shorten the Motor lifetime.

Life time

DC Motor lifetime varies according to different use conditions and load, so different working condition will cause different lifetime for the same motor, please let us know your exact using condition, we will design the motor according to it.

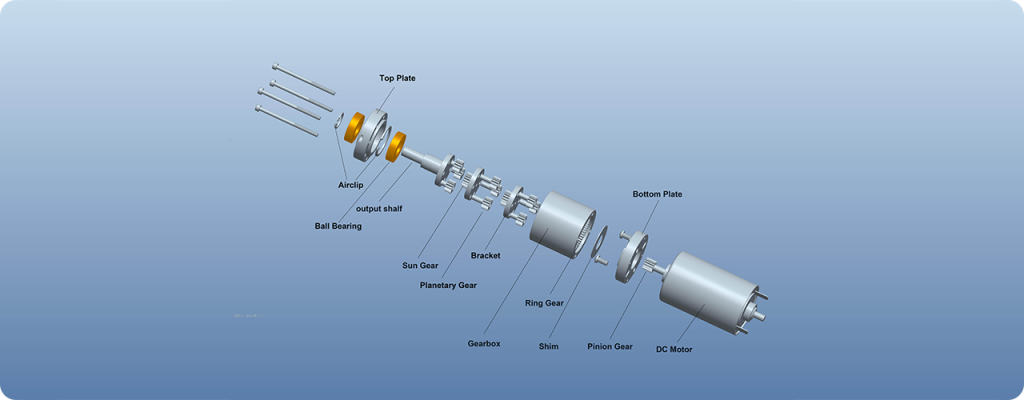

Planetary Gear Motor

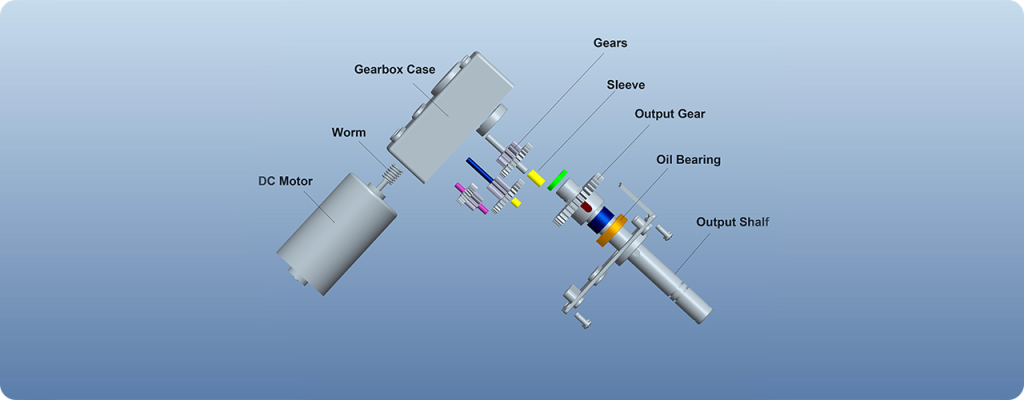

Worm Gear Motor

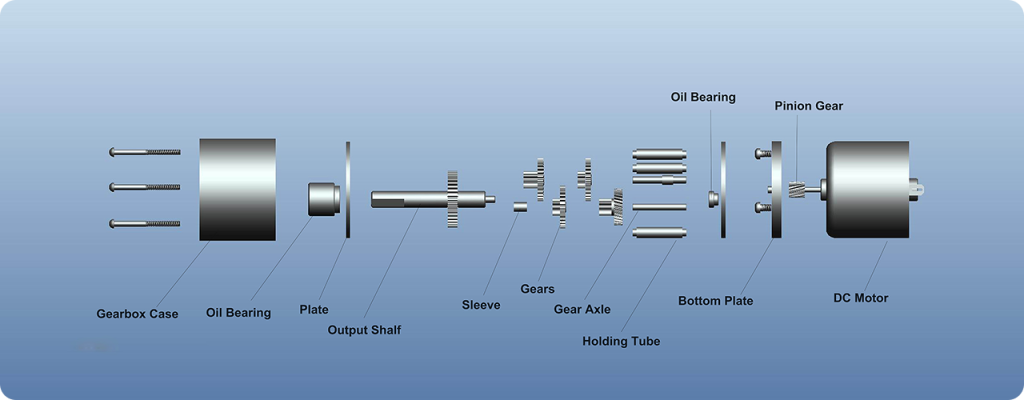

DC Spur Gear Motor

Right Angle Spur Gear Motor

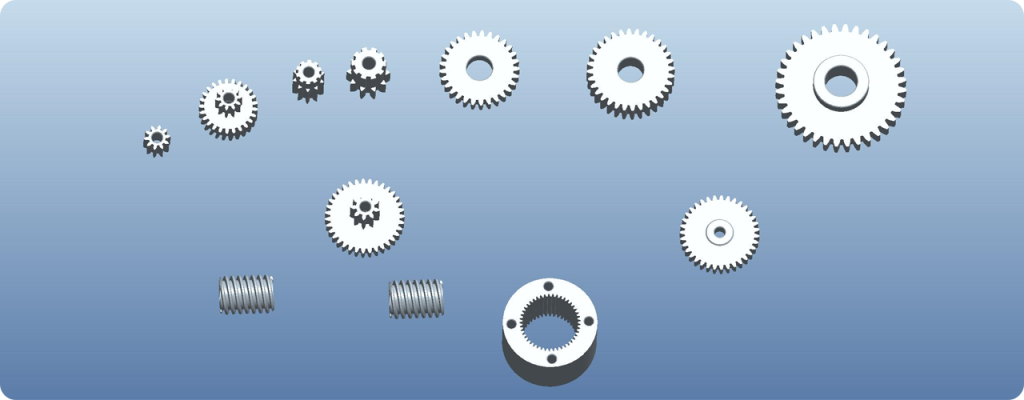

Gear

Frequently Asked Technical Questions

Are you a manufacturer or a trading company?

We are a manufacturer. We are specialized in design, manufacture and sales of DC Gear Motor.

How much space does your factory occupy?

Our factory covers an area of 2800 square meters

How many people are in your factory?

We have more than 30 workers in our factory

How to choose a suitable DC gear motor

To choose a suitable DC gear motor, pls advise our sales about your requirements for the voltage, speed and torque of the motor, as well as the application and space limit if any. These messages will be transfered to our R&D team to work out proposals.

How to order samples for test?

If our proposals with quotes are approved on your side, pls send us your contact information. Our sales will issue profoma invoice for you. Once the invoice confirmed and payment released, sales will submit the samples request to engineering deparment. As soon as finished samples, the samples will be delievered to your place in negotiated methods.

How long it will take for you to proceed samples?

For samples, the lead time is normally 2-3 weeks after order confirmed. For some special customized components, sales would send notice in advance, that would be a few days more.

What is the shipping terms?

For samples, we usually use Ex work terms. For production, Ex work and FOB Shzhen are both available.

What are the shipping methods?

For samples, we usually use express methods, like DHL, FedEx, TNT etc. Pls advise us your express account once you would like to use your own to ship the goods. For production, express, air shipment, boat shipment are all available. Pls advise the contact once you have your own shipping agent.

How to make a bulk order?

For every samples, there is an attached sample datasheet. Pls let us know if the samples are approved, or any improvements before bulk order. To proceed the shipment, our R&D will issue the controlled guide specs based on the sample datasheet and your feedback in our system. All the guidance for production and QC will be listed on the drawing. All the goods will be produced and checked based on the drawing, the drawing can be revised only with your requests.

Can you provide free samples?

We do not provide free samples.

What is the warranty of your motor?

The warranty of our motors is 12 months after receiving our goods, without any stall use.

What is payment terms?

The normal payment term is advance payment. For sample long-term cooperated clients, we can negotiate about 50/50 payment terms. For samples, paypal is available. For production, bank transfer is accepted.