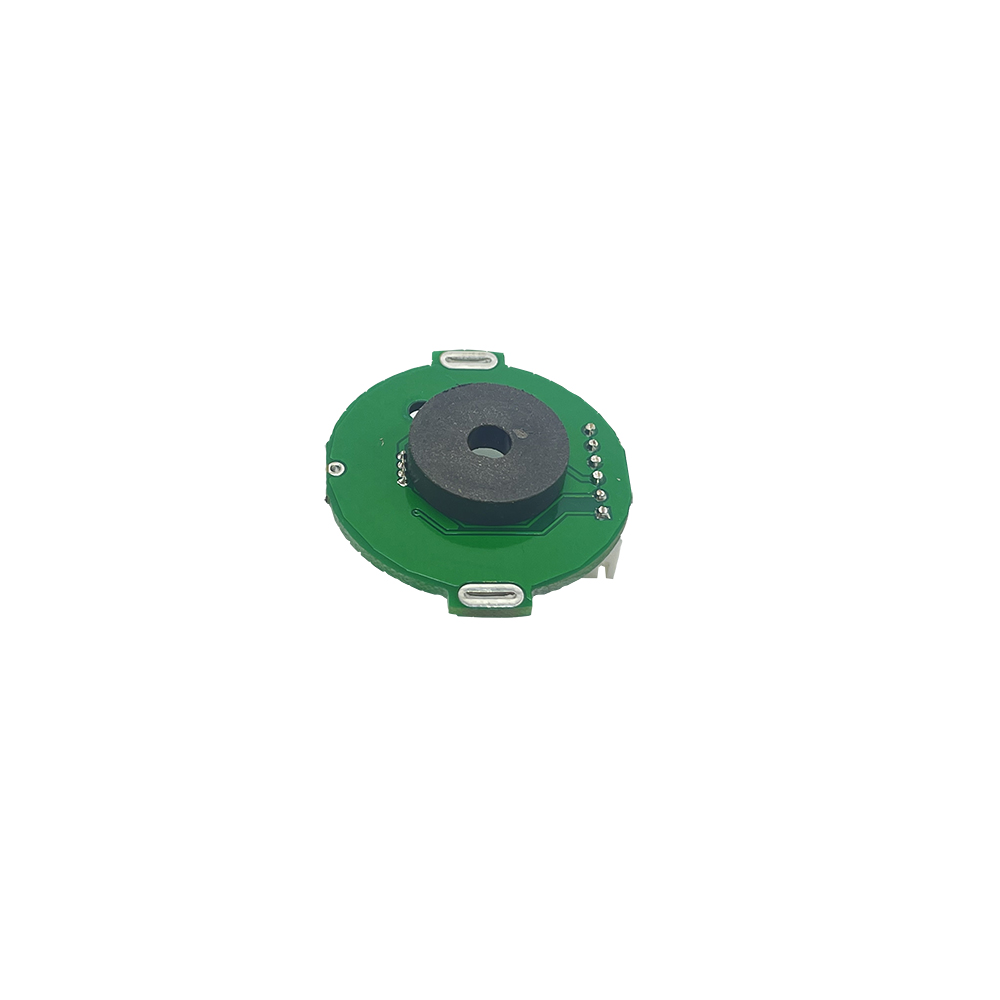

What is DC Motor Encoder?

DC motor encoders are used for speed control feedback in DC motors where an armature or rotor with wound wires rotates inside a magnetic field created by a stator. The DC motor encoder provides a mechanism to measure the speed of the rotor and provide closed loop feedback to the drive for precise speed control.

Main Products

Benefits of DC gear motor

- High Torque, High Detent Torque, High RPM, Low Noise, Small Backlash, High Precision

- Durable and High efficiency, Small Cogging Torque

- Compact size, Customized Shaft direction

- High Durability, Waterproof, Long Lifespan

- Higher Speed Range, buit-in Driver

Why Choose DONGMING MOTOR

Innovative R&D Engineering for Your Project

- Considering the rationality and convenience of the production process from the design stage.

- If our existing “standard” DC gear motor cannot provide the optimal performance, we R&D team will work with you to develop customized DC gear motor solution.

Modernized High Volume Manufacturing

4+ semi-automatic production lines, 2400000PCS DC gear motors/month

Quality & Reliability Policy

- Considering the rationality and convenience of the production process from the design stage

- Adopting the international advanced quality management system, strict management of IQC, production and QA

Effective Communication and Collaboration

- Customer needs analysis team respond to customer quickly and professionally

- Professional sale engineers provide one-stop customized services

Professional R&D engineer team work for you

From developing&research, prototype, testing, small batch test, mass production and after-sales service

Start the Custom Service for Your Project

Requirements discussion

To ensure providing the best solution of DC gear motor, the sales engineers should discuss with customer some important infomation including:

- The installation dimension for DC gear motor

- The parameter for DC gear motor includes operation load speed, operation load torque, voltage, output load current,stall torque, stall current, work cycle, working condition, noise level, lifetime,Electromagnetic shielding, etc

- The certification requirements, such as CE, ROHS, SGS, TEACH.

- The target cost and project plan.

Project Evaluation

According customer’s requirments for DC gear motor and other information of project, our R&D team analyst and evaluate the project. And to confirm provide our exsiting solution or build a new solution. If to design a new DC gear motor, DONGMING design team will provide the project evaluation report for the development time, mold cost and risk.

Prototype sample manufacturing

To confirm all requirements with customers step by step, our R&D will utilize the design software to design a product or set a 2D/3D drawing for DC gear motor.

Sample performance test

When the sample is completed, our R&D team will test the DC gear motor’s all performance with our precise test equipment. If customers have lifetime requirement, we will provide the lifetime cycle test in laboratory.

Small batch production and mass production

Start a trial production after sample working perfectly on product. Launch small batch to test customers’ market.

Finally start the mass production

We have the compeleted quality control system for production.

Delivery and after-sales service

When products ready to ship, we are also responding for logistics to make sure customer picks up all products satisfied.

If customers have any issue after sales, our team will support to solve it always.

DC Motor Types

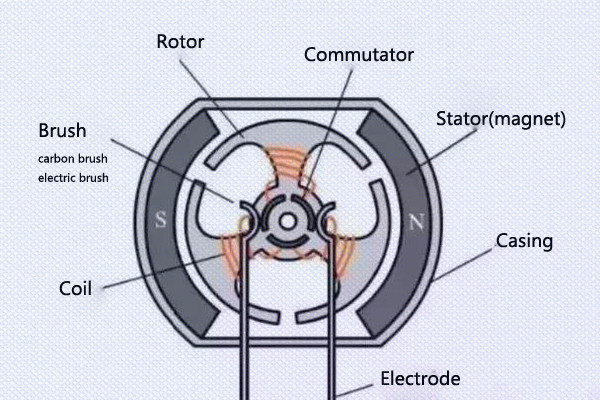

Brushed DC Motor

Brushed DC motors work by having the coil rotate inside the surrounding magnets. The rotation of the coil causes the contact between commutator and brush to alternate, therefore switching the current flow through the coil. As a result, the brushed DC motor can operate.

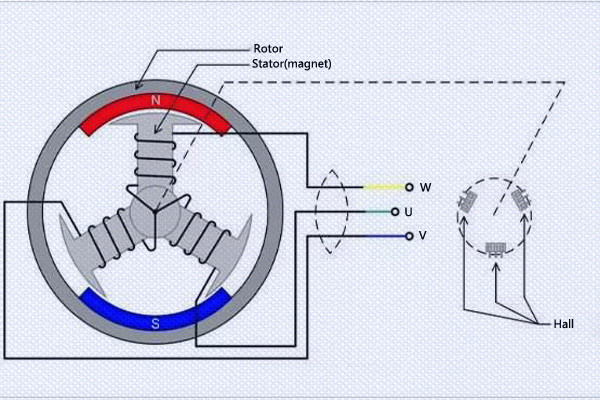

Brushless DC Motor

A Brushless DC Motor (BLDC) is an electric motor powered by a direct current voltage supply and commutated electronically instead of by brushes like in conventional DC motors. BLDC motors are more popular than the conventional DC motors nowadays, but the development of these type of motors has only been possible since the 1960s when semiconductor electronics were developed.

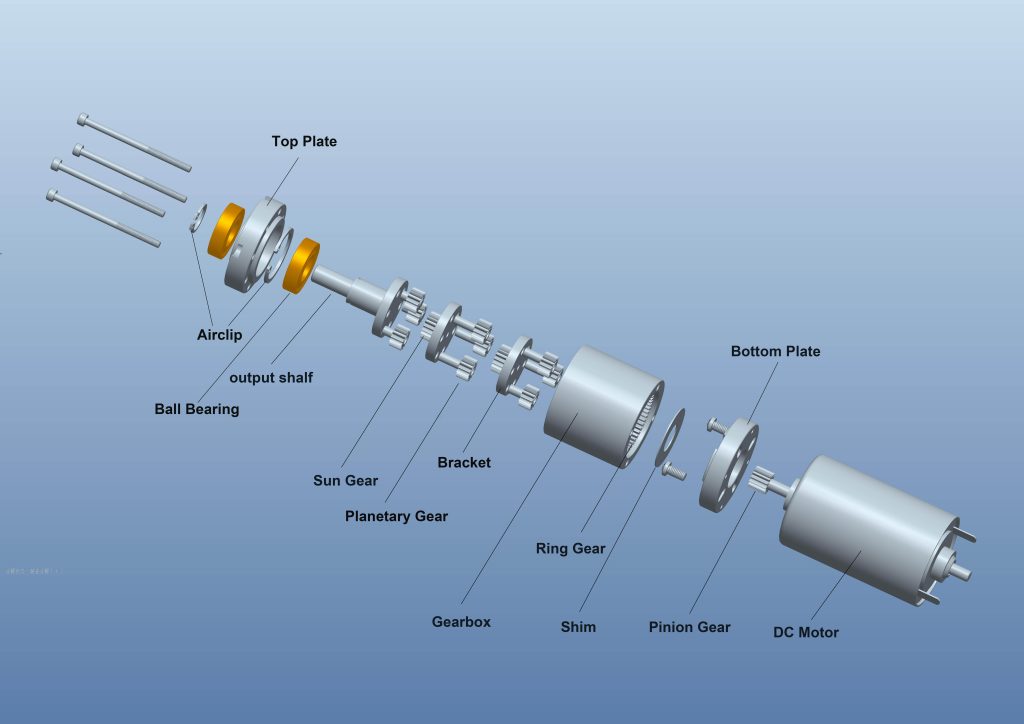

Gearbox Types

Spur Gearbox

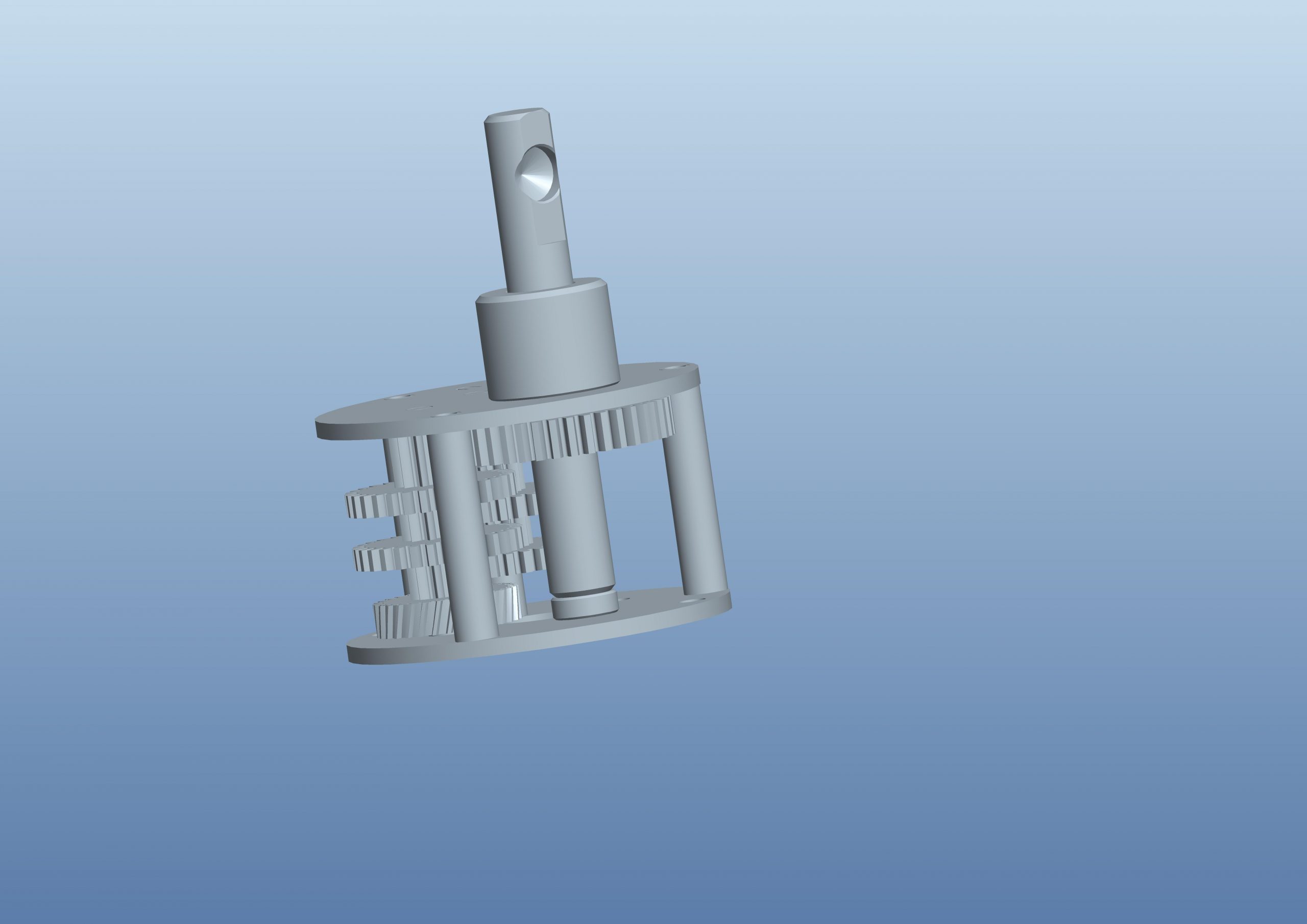

Spur gears are used in mechanical applications to increase or decrease the speed of a device or multiply torque by transmitting motion and power from one shaft to another through a series of mated gears.Spur gears are more efficient compared to helical gears with the same size. They are quite reliable and offer constant velocity. Spur gears are also considered a member of positive transmission because they don't have any slippage

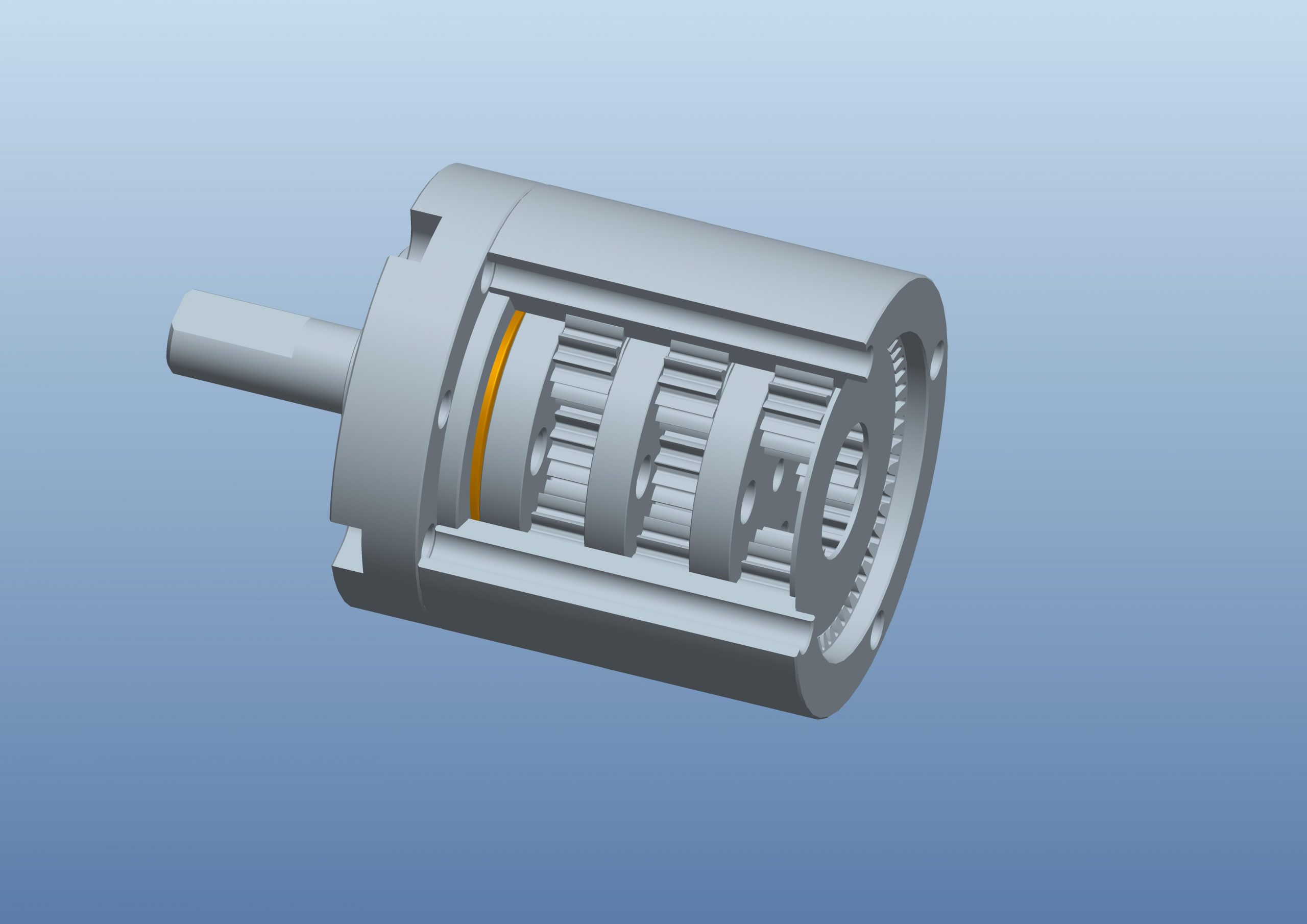

Planetary Gearbox

A planetary gearbox is a gearbox with the input shaft and the output shaft aligned. A planetary gearbox is used to transfer the largest torque in the most compact form (known as torque density).Planetary gear systems are able to produce a lot of torque because the load is shared among multiple planet gears. This arrangement also creates more contact surfaces and a larger contact area between the gears than a traditional parallel axis gear system.

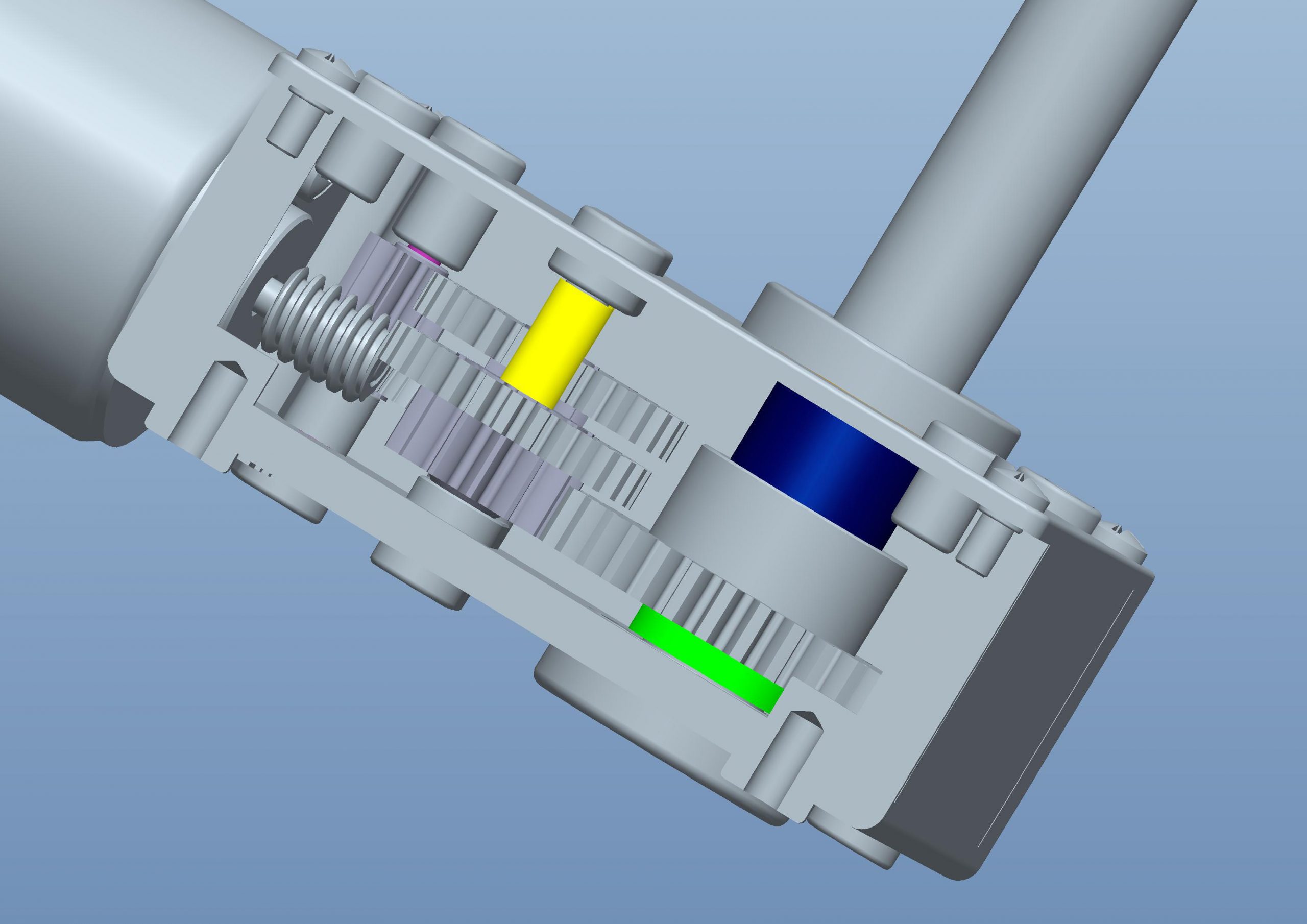

Worm Gearbox

Worm gears operate by the friction created by turning lubricated gears. The friction is then converted into heat. By producing a low speed and high-speed torque level, worm gears are utilised as speed reducers, which implies that they are ideal for several applications. In theory, a worm gear is self-locking when the static friction angle is larger than the helix angle of the worm. The static friction angle is described as the angle where the load above will start to move.