Spur Gear Motor

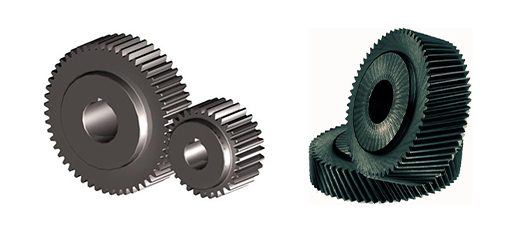

A DC spur gear motor is an electric motor that transmits power from the motor to the output shaft using straight-toothed gears. DC motors with spur gears use gears to transmit power from the motor to the output shaft. The teeth of the gears, which are placed in a straight line, mesh with one another gear to transmit motion and power.

The DC spur gear motors transfer power from the motor to the output shaft using the same fundamental straight-toothed gearing but it differ in sizes such as 16mm dc gear motor, 25mm dc gear motor, 37mm gear motor, 13mm, 20mm, 2 27mm, 30mm, 32mm, 33mm, 50mm DC gear motors.

Spur gearheads have a single contact point at any time. This means that any load is held entirely by a single point of contact between two gears.

DONGMING’s spur gear motor is customized according to the customer’s product application. It can be customized in terms of shaft, voltage, rpm, torque, current, power, cable, noise level.

We have existing spur gearboxes and motors to meet your needs for speed, torque, current and voltage. If the existing gearboxes and motors cannot meet the requirements, we can customize them.

Dongming can provide 3V Spur gear motor, 6V spur gear motor, 12V spur gear motor, 24V spur gear motor. The speed can be provided at 25 rpm gear motor,12v 100 rpm dc geared motor,dc gear motor 500 rpm,dc gear motor 60 rpm, etc. Because spur gear motors gearedhead is spur gearedhead, it also calls spur gear head motor.

Our most advantage is that we can provide very low noise DC Spur Gear Motors to you. There are come special customization in plastic gear, Brushed DC motor, Brushless DC motor.

Spur Gear Motor

DC Spur Gear motor

Diamater: 12mm

Voltage: 3~12VDC

Speed: 1~2000rpm

Torque: 0.02~2kg.cm

DC Spur Gear motor

Diamater: 16mm

Voltage: 3V~12VDC

Speed: 9RPM~1000RPM

Torque: 0.08kg.cm~2.5kg.cm

DC Spur Gear motor

Diamater: 27mm

Voltage: 5V~12VDC

Speed: 4RPM~400RPM

Torque: 0.4kg.cm~6kg.cm

DC Spur Gear motor

Diamater: 27mm

Voltage: 3V~12VDC

Speed: 3RPM~400RPM

Torque: 0.15kg.cm~3kg.cm

DC Spur Gear motor

Diamater: 30mm

Voltage: 6V~24VDC

Speed: 3RPM~250RPM

Torque: 0.6kg.cm~7kg.cm

DC Spur Gear motor

Diamater: 33mm

Voltage: 6V~24VDC

Speed: 3RPM~450RPM

Torque: 0.6kg.cm~17kg.cm

DC Spur Gear motor

Diamater: 37mm

Voltage: 6V~24VDC

Speed: 2RPM~900RPM

Torque: 0.16kg.cm~10kg.cm

DC Spur Gear motor

Diamater: 37mm

Voltage: 6V~24VDC

Speed: 6RPM~500RPM

Torque: 0.6kg.cm~30kg.cm

DC Spur Gear motor

Diamater: 37mm

Voltage: 12V~24VDC

Speed: 2RPM~700RPM

Torque: 0.5kg.cm~30kg.cm

DC Spur Gear motor

Diamater: 50mm

Voltage: 12V~24VDC

Speed: 10RPM~600RPM

Torque: 0.5kg.cm~60kg.cm

Benefits of DC Spur Gear Motor

- High Torque, High Detent Torque, High RPM, Low Noise, Small Backlash, High Precision

- Durable and High efficiency, Small Cogging Torque

- Compact size, Customized Shaft direction

- High Durability, Waterproof, Long Lifespan

- Higher Speed Range, buit-in Driver

Why Choose DONGMING MOTOR

Innovative R&D Engineering for Your Project

- Considering the rationality and convenience of the production process from the design stage.

- If our existing “standard” DC gear motor cannot provide the optimal performance, we R&D team will work with you to develop customized DC gear motor solution.

Modernized High Volume Manufacturing

4+ semi-automatic production lines, 2400000PCS DC gear motors/month

Quality & Reliability Policy

- Considering the rationality and convenience of the production process from the design stage

- Adopting the international advanced quality management system, strict management of IQC, production and QA

Effective Communication and Collaboration

- Customer needs analysis team respond to customer quickly and professionally

- Professional sale engineers provide one-stop customized services

Professional R&D engineer team work for you

From developing&research, prototype, testing, small batch test, mass production and after-sales service

Custom Service of Spur Gear Motor for Your Project

Requirements discussion

To ensure providing the best solution of DC Spur gear motor, the sales engineers should discuss with customer some important infomation including:

- The installation dimension for DC gear motor

- The parameter for DC gear motor includes operation load speed, operation load torque, voltage, output load current,stall torque, stall current, work cycle, working condition, noise level, lifetime,Electromagnetic shielding, etc

- The certification requirements, such as CE, ROHS, SGS, TEACH.

- The target cost and project plan.

Project Evaluation

According customer’s requirments for DC gear motor and other information of project, our R&D team analyst and evaluate the project. And to confirm provide our exsiting solution or build a new solution. If to design a new DC gear motor, DONGMING design team will provide the project evaluation report for the development time, mold cost and risk.

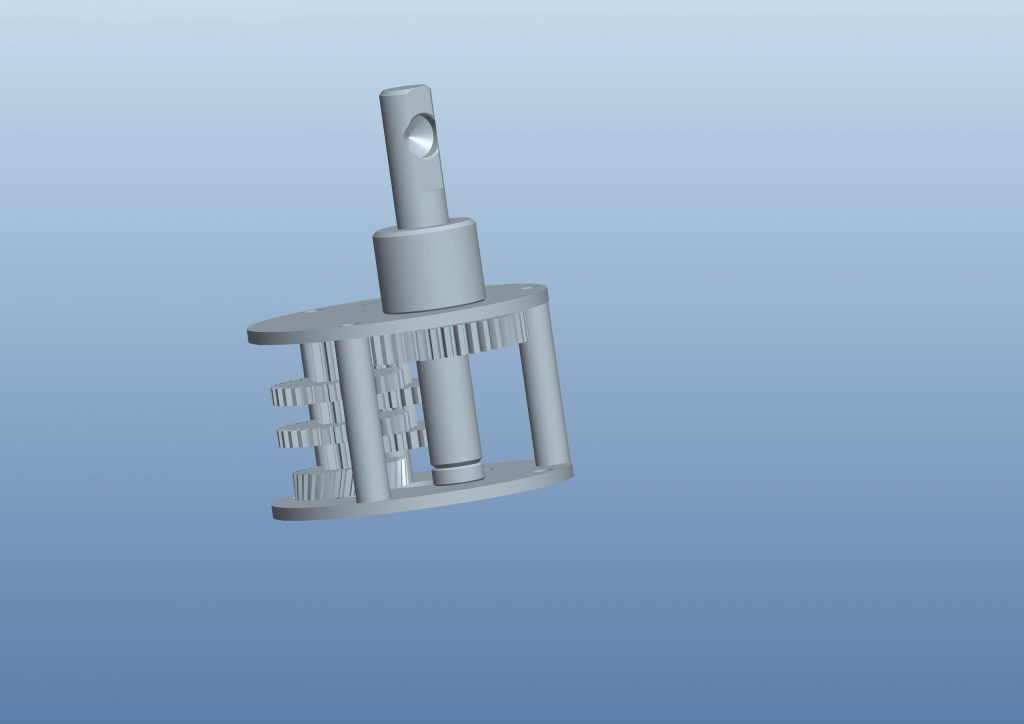

Prototype sample manufacturing

To confirm all requirements with customers step by step, our R&D will utilize the design software to design a product or set a 2D/3D drawing for DC gear motor.

Sample performance test

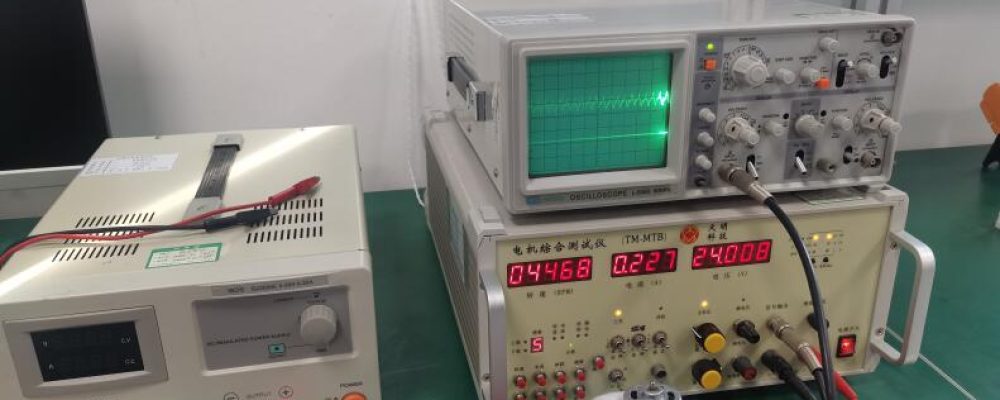

When the sample is completed, our R&D team will test the DC gear motor’s all performance with our precise test equipment. If customers have lifetime requirement, we will provide the lifetime cycle test in laboratory.

Small batch production and mass production

Start a trial production after sample working perfectly on product. Launch small batch to test customers’ market.

Finally start the mass production

We have the compeleted quality control system for production.

Delivery and after-sales service

When products ready to ship, we are also responding for logistics to make sure customer picks up all products satisfied.

If customers have any issue after sales, our team will support to solve it always.

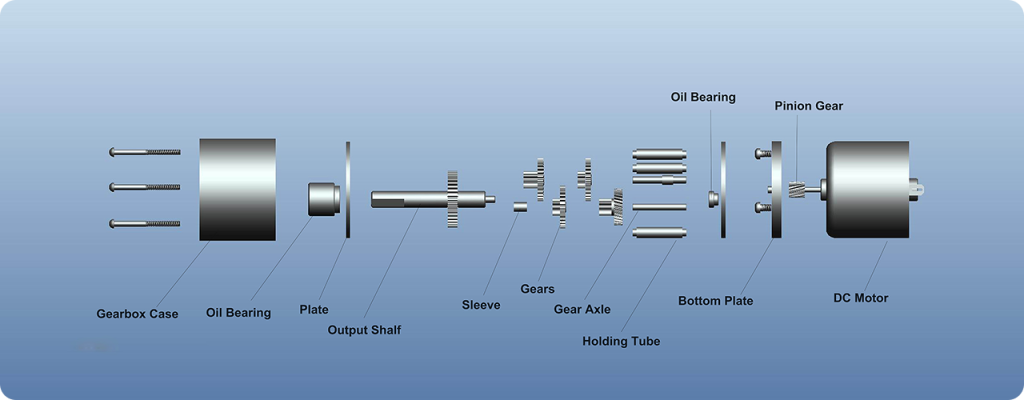

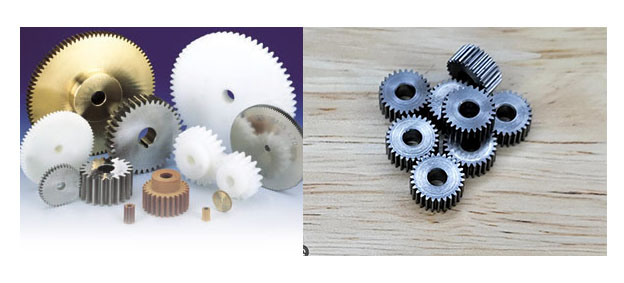

Gearbox of Spur Gear Motor

Spur Gearbox

Spur gears are used in mechanical applications to increase or decrease the speed of a device or multiply torque by transmitting motion and power from one shaft to another through a series of mated gears.Spur gears are more efficient compared to helical gears with the same size. They are quite reliable and offer constant velocity. Spur gears are also considered a member of positive transmission because they don’t have any slippage

Application

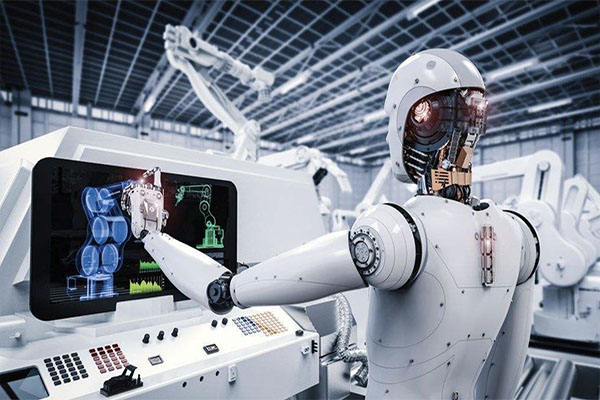

Robotics

From robotic arms to teaching robotics and robotic toys, spur gear motor play a crucial role in facilitating precise and controlled movements.

Sanitary Automations

In dispensers, lid openers, and sensor sanitary bins, spur gear motor contribute to the seamless functioning of sanitary automation systems.

Safe and Security Systems

Electronic locks, door locks, safes, and latch closers benefit from the reliability and efficiency of spur gear motor.

Valve/Meter Mechanisms

Electric valves, gas meters, and water meters leveragespur gear motor for optimal performance.

Curtain Automation

Electric curtains and blinds are enhanced with the controlled and efficient movement provided by spur gear motor.

Coffee Machines

In the realm of coffee machines, including coffee makers and bean grinders, spur gear motor ensure precise and reliable operations.

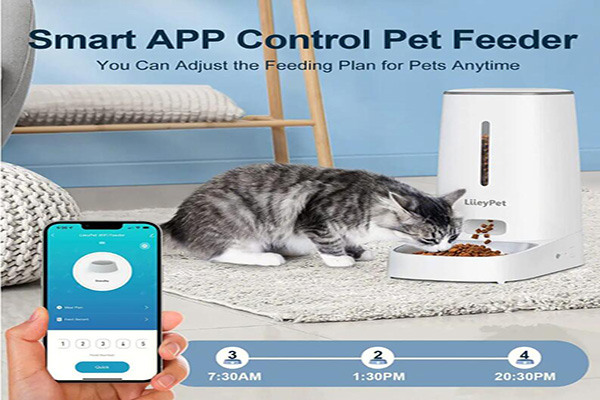

Pet Care Devices

From anti-bark devices to pet feeders and door openers, spur gear motor contribute to the comfort and well-being of our furry friends.

Bank Automation

ATMs, coin counters, coin selectors, coin validators, and banknote counters benefit from the precision and durability of spur gear motor.

Vending Machines

Beverage vending machines, hot and cold drink dispensers, and juicer makers rely on the efficiency and reliability of spur gear motor.

Medical Care Equipment

Diagnostic equipment, medical beds, massagers, and beauty care appliances are empowered by the precision movements of spur gear motor.

Others

From BBQs and 3D printing to baby cradles, fish feeders, humidifiers, and range hoods, spur gear motor find applications in a diverse array of industries and products.

What You need to know for Spur Gear Motor?

Looking for the perfect DC spur gear motor for your application? Our guide covers everything you need to know, from 12mm to 50mm DC spur gear motor. Discover how to choose the right operation voltage, load speed, load torque, shape and size for your needs. With our tips on selecting the best DC spur gear motor, you can ensure reliable performance and maximum efficiency.

Have you ever wondered how machines can perform such precise tasks with such smooth movements? All because of gear motors! Electric motors with spur gears transmit power from the motor to the output shaft using gears with straight teeth. Conveyor belts, packaging equipment, and power tools are just a few of the industrial and domestic uses for them. Spur gear motors are widely known for their outstanding efficiency and low maintenance needs while producing exceptional torque and speed. These machines slow down their running speed and boost their torque value by combining reduction mechanisms with regular machines, making them ideal for applications where accuracy is crucial.

The ideal gear motor with the appropriate reduction capabilities is crucial for supplying the optimum amount of power for your application because power is a function of both torque and speed. Gear motors can be used to power high-power machines for industrial applications or small, powerful machines for home appliances.

The goal of this page is to present a thorough review of DC spur gear motor, including everything from their fundamental parts and modes of operation to their uses and upkeep. This article has all the information you need, whether you’re an engineer wanting to develop a new piece of machinery or simply interested in how DC spur gear motor operates.

What is DC spur gear motor?

DC motors with spur gears use gears to transmit power from the motor to the output shaft. The teeth of the gears, which are placed in a straight line, mesh with one another gear to transmit motion and power. A spur gear motor is an electric motor that transmits power from the motor to the output shaft using straight-toothed gears. The DC spur gear motor transfers power from the motor to the output shaft using the same fundamental straight-toothed gearing but it differ in sizes such as 12mm, 13mm, 16mm, 20mm, 25mm, 27mm, 30mm, 32mm, 33mm, 37mm, 50mm DC spur gear motors.

These motors are frequently employed in systems like Smart Home, Robotics, Health Medical Care, Industrial & Commercial products, Valve & Meter, Vending Machine, automotive, Consumer Electronics that need intelligent automation. This motor is well versed as it can be applicable in various smart home appliances such as Electric Blinds, Range Hood, Capsule Coffee Machine, Coffee Machine, Sensor Trash Can, Smart Toilet, Auto Pet Feeder, auto paper towel machine. Lawn Mower Robot, Sweeping Robot, Electric Valve, drink vending machine, Baby formula maker, etc

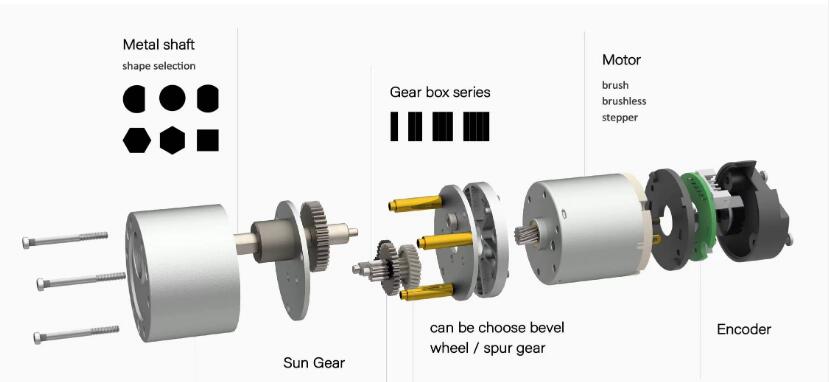

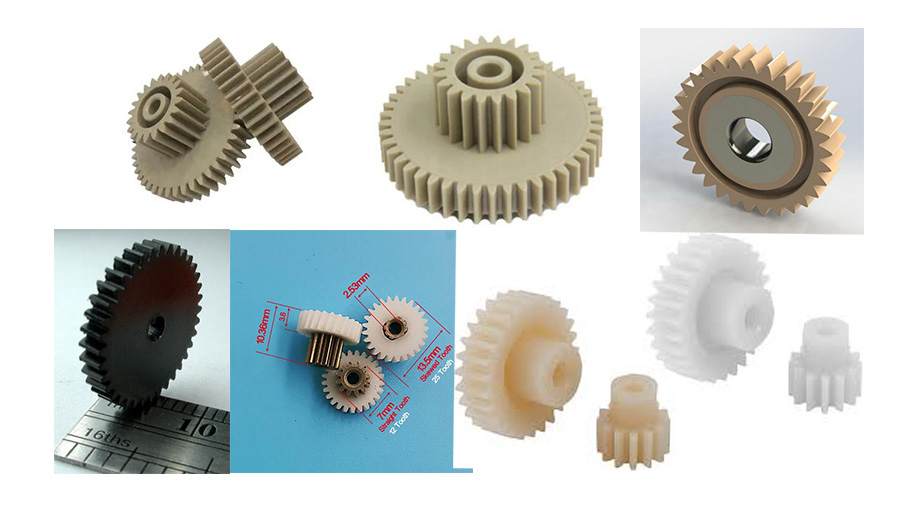

A DC motor, a gearbox, and a output shaft are the three main parts to take into account while thinking about DC spur gear motor. Together, these parts produce a high torque and speed as well as precise and dependable performance. With options for various sizes, materials, and mounting configurations, the shaft can be tailored to fit various applications.

The gearbox contains the majority of the spur gears which is in charge of transferring the torque from the motor to the output shaft and its round shape makes it suitable for applications with limited space. The rounded-shaped gearbox give rise to the term “round spur gear motor” which are more favorable chosen in the engineering space due to low cost, easily customization are compact shaped which makes it fit across many applications. The shafts in the round gear motors either be located in the center or not.

Types

Another criterion for the categorization of DC spur gear motor is the voltage output. These motors are available in a range of voltages, including 6V, 12V, and 24V, and are often used in battery-powered devices such as toys and small appliances. For larger applications needed by heavy machinery industry, you can get the motor at wholesale.

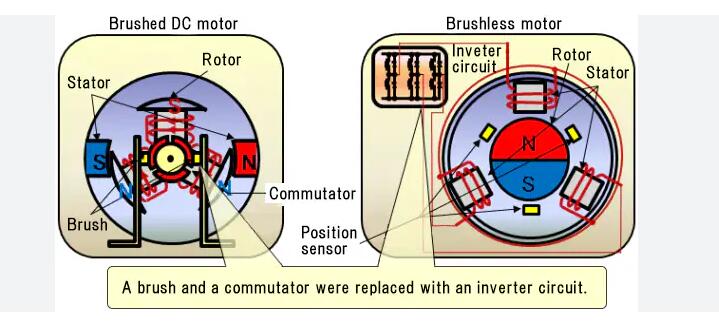

For custom needs, DC Spur gear motor can be re-engineered which could includes a variety of extra features and parts, including shafts and gearheads of various types, motors (brushed or brushless), and more. These features can impact the motor’s performance and suitability for different applications.

A DC spur gear motor’s primary role is to convert electrical energy into mechanical energy and to give torque and speed to various applications and machinery.

Below are the advantages and disadvantages of DC Spur Gear Motor

Benefits:

- Simple and reliable construction

- High efficiency

- Low noise

- High torque output

- Compact size

- Versatile in terms of speed and torque options

- Easy to maintain and repair

- Cost-effective compared to other types of gear motors

Drawbacks:

- Limited speed range

- Lifespan is no longer than planetary gearhead.

- Requires careful lubrication and maintenance to prevent wear and tear

- Not ideal for high shock loads or sudden changes in direction

- Can be prone to backlash and wear over time

- Limited range of materials available for gear construction, which can limit compatibility with certain applications

- Easy to mount

How To Increase Torque of DC Spur Gear Motor?

As you may already be aware, a torque is the force that can cause an item to twist. Torque is the force used to spin or twist an object around an axis, such as turning a doorknob. The force you apply and the distance you apply it from the axis determine how much torque is generated. Torque is the amount of force that a Dc motor can generate to turn a shaft. A motor’s ability to generate torque is influenced by a variety of elements, including the amount of current it receives, its size and power, DC motor, Winding of DC motor, magnetic stripe and the gear ratio it has with the load.

To increase the torque of the motor, below are the 3 most efficient ways to increase the torque of a DC spur gear motor:

1.Changing the gear ratio can increase the torque output of the motor using a big modulus gear. This is because a higher gear ratio results in a higher torque output at the output shaft of the motor which is possible by the addition of a gearbox. Both the gearbox and gear ratio are used by engineers to manipulate the torque of the motor.

2. Increasing the current and voltage supplied to the motor can increase the torque output by generating a higher rotational force in the output shaft. Caution should be taken as this could increase the heat generated by the motor and damage the motor.

3. When added to the gearbox, magnetic ferrite tiles can boost the torque output of a motor. Ferrite is the perfect material for magnets because of its high magnetic permeability and low electrical conductivity. The interaction between the magnetic field of the motor and the gearbox is intensified by raising the magnetic field inside the gearbox, leading to a greater torque production at the gearbox’s output shaft.

Choosing the perfect motor: consider these.

In the following paragraphs, you would be given some of the things to look for while choosing a gear motor for your next ground-breaking application. The first and most important is the power source of which the DC spur gear motor is the best to choose as it conserve energy and are more compact.

Other integral determinants to choosing a spur gear motor are the size (ranging from 12mm to 50mm spur gear motor) and voltage generated which could range anywhere from 6V to 24V depending on your choice. Consider the motor’s Speed, which can range from low 2RPM to high 500RPM, if you require a motor that runs at a specified pace.

Another necessary aspect to take into account is the motor’s torque. A 12V spur-gear motor might be an excellent option if you require a motor with high torque output. Encoders, which you may use to track the position of the motor shaft, are also included with some motors.

Finally, you should think about how the motor will be used. A motor must be able to manage the load and supply the required power if it is to be used for a specific purpose, such as in Robotics, Valve, Vending machine, etc.

In conclusion, it’s critical to take into account variables like the motor type(shape), dimension, voltage, current, rated speed, rated torque, stall torque, static torque, encoder, output shaft, noise, and application when choosing a suitable motor for your application. The drawbacks of a DC gear motor can be lessened by carefully choosing the gear materials and lubricants, leading to durable and effective functioning. The appropriate gear motor can make all the difference in obtaining optimal performance because they are a crucial part of many machines and appliances. Versatile, highly effective, low maintenance, and able to deliver high torque and speed in a small frame, spur gear motors are a favored option for many engineering developments.

Learn how to reduce noise in DC gear motors and extend their lifespan by utilizing specific materials and lubricants. Discover how these factors impact the overall performance and suitability of a DC spur gear motor for your specific application. Find out effective methods to test the performance of a spur gear motor for optimal results.

How to reduce noise for DC spur gear motor?

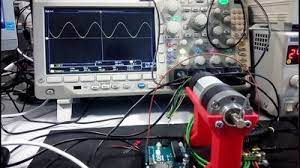

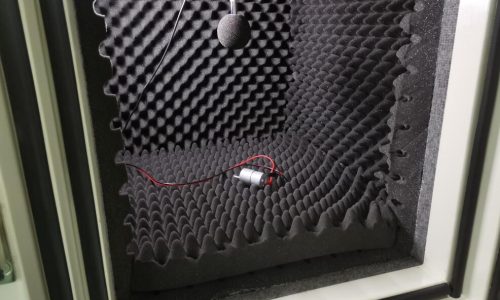

Noise Test:

DC Spur gear motor can occasionally generate excessive noise during operation, which can be distracting or even dangerous in specific environments. There are, fortunately, numerous actions that may be performed to minimize noise levels and make DC spur gear motor quieter. Here are some pointers:

- Select high-quality gears: Noise levels can be reduced by using high-quality gears with precision manufacturing and little runout. Look for gears constructed of strong materials, such as steel, brassand powder metallurgy that can resist severe use without quickly wearing out.

2. Use plastic gears or special material plastic gear: Because they have more give and can absorb vibrations, plastic gears are frequently quieter than metal gears. They also produce less wear debris, which can add to noise over time. The plastic gear can be employed as the first stage in the gearbox.

3. Use low-speed DC motors: Low-speed DC motors produces less noise than their counterpart which are higher-speed motors. You can lower the overall noise output of the spur gear motor by using a low-speed motor.

4. Use high-quality grease: High-quality grease can assist minimize friction and noise levels between gears. Look for grease that is specifically developed for use with spur gear motors and follow the manufacturer’s instructions.

5. Optimize gearbox design: Gearbox design can have a considerable impact on noise levels. You can help reduce noise production by improving the design to reduce vibration, enhance gear mesh, and minimize backlash.

Creating a highly efficient DC spur gear motor with less noise is our priority as Gear Manufacturers. Following the tips above could help reduce noise pollution with this awesome application and using the gear according to the standard slated out. Additionally, you as the engineers need to follow the manual and consult with a qualified technician to help improve the overall efficiency of the gear.

What determines the lifespan of a DC spur gear motor and what can be done to increase its lifespan?

A DC spur gear motor’s durability can be impacted by a number of things. In most cases, the manufacturers would have specified the lifetime of the gear motor in the manual actually due to the materials used and other technical details.

The quality of the gear materials used in the motor’s manufacture is a significant consideration. Using high-quality gear materials can assist to guarantee that the gears do not wear out or break early, hence extending the motor’s lifespan. Using a box for DC motors can also assist to protect them from dust and other environmental variables that might cause premature failure.

Utilize a DC motor with a low speed. Make sure to utilize the motor properly to prevent any potential problems like short circuits. The DC spur gear motor should not be allowed to stall for extended periods of time since this might cause current very high and perhaps harm the motor.

A DC spur gear motor’s maximum torque capacity should not be exceeded. Excessive strain and increased noise generation can arise from operating the motor past its specified torque limit. To guarantee correct use, always refer to the manufacturer’s specs and instructions.

The type of motor used can also have an impact on the longevity of a spur gear motor. Brushless motors feature fewer moving components than brushed motors, which can assist to decrease wear and tear over time. Brushless motors have a generally long duration period than brushed motors thereby saving you the stress of changing the gear over time.

It is critical to utilize a spur gear motor according to the manufacturer’s instructions to assist extend its longevity. This comprises operating the motor within the parameters of voltage, current, torque, and other variables. Using the motor outside of its specs might put it under extreme stress and lead it to fail prematurely. Lubrication and cleaning on a regular basis can also assist to improve the lifespan of a spur gear motor. The few tips listed above can go a long way to help relieve your stress and save you time and money by elongating the durability of the specified gear of your choice.

What are the differences between stall torque, rated torque, stall current, and rated current for DC spur gear motors?

The rated torque and stall torque are two crucial words to comprehend when it comes to DC spur gear motor. The same is true of Rated and Stall Current.

The rated torque indicates the maximum continuous torque that the motor can safely deliver without overheating or experiencing excessive wear. It is the continuous torque generated while the gear is functioning. By measuring the rated torque, you can assess whether the motor possesses enough power to meet the demands of your application.

The stall torque, on the other hand, represents the maximum torque that the motor can generate when power is applied, while the shaft is prevented from rotating (i.e. rotational speed is zero). Understanding the stall torque allows you to gauge the motor’s strength and its ability to handle sudden load spikes or resistance in your application.

The maximum current passes through the DC spur gear motor while it is not spinning, whereas the rated current is the maximum current that the motor is designed to handle during normal operation.

When selecting a DC spur gear motor, it is critical to evaluate both the rated torque and the stall torque to ensure that the motor can satisfy your specific requirements. The application, load requirements, and ambient variables can all have an impact on the motor’s performance.

When looking for a DC spur gear motor, it is critical to conduct research on several models in order to get the greatest alternative for your unique application.

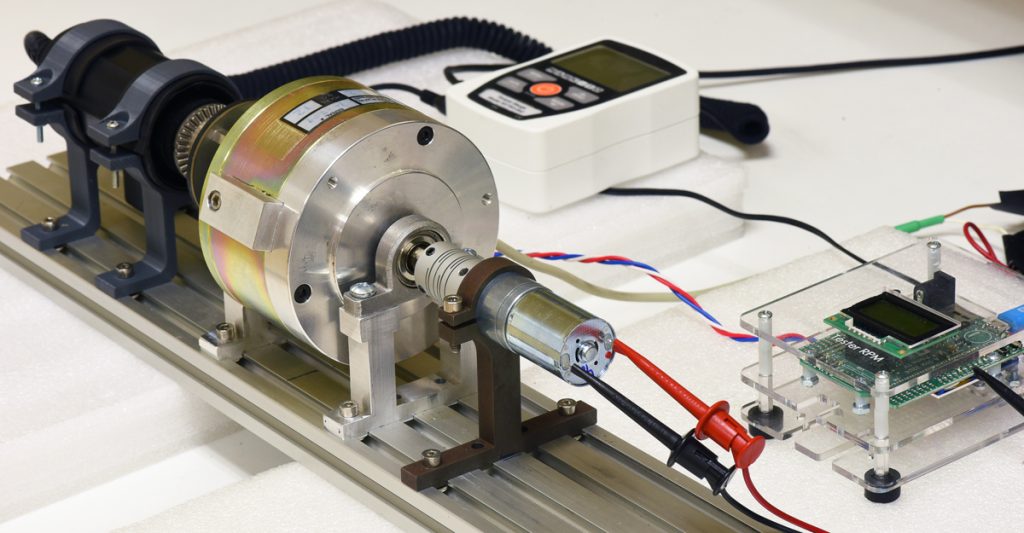

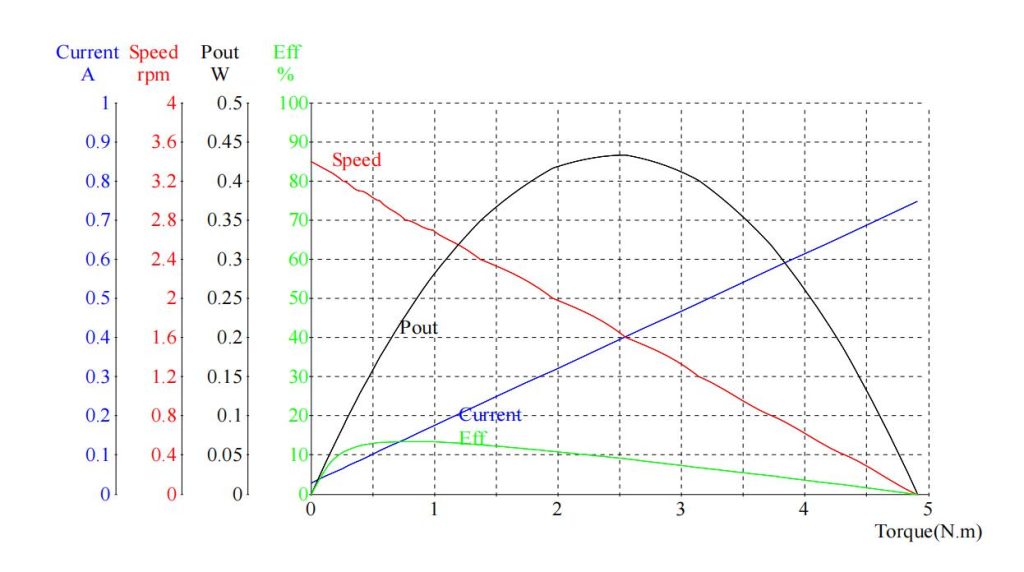

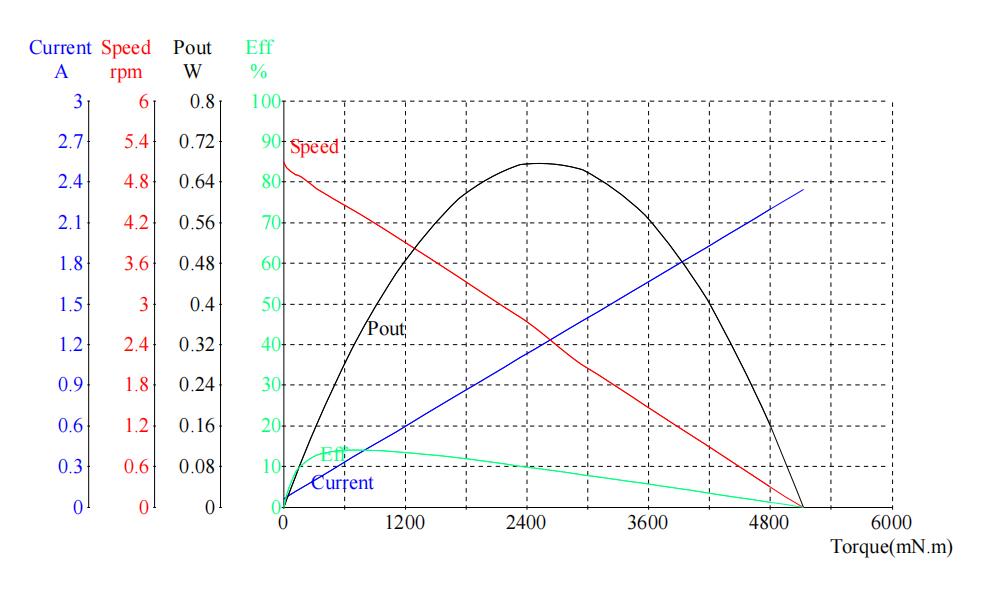

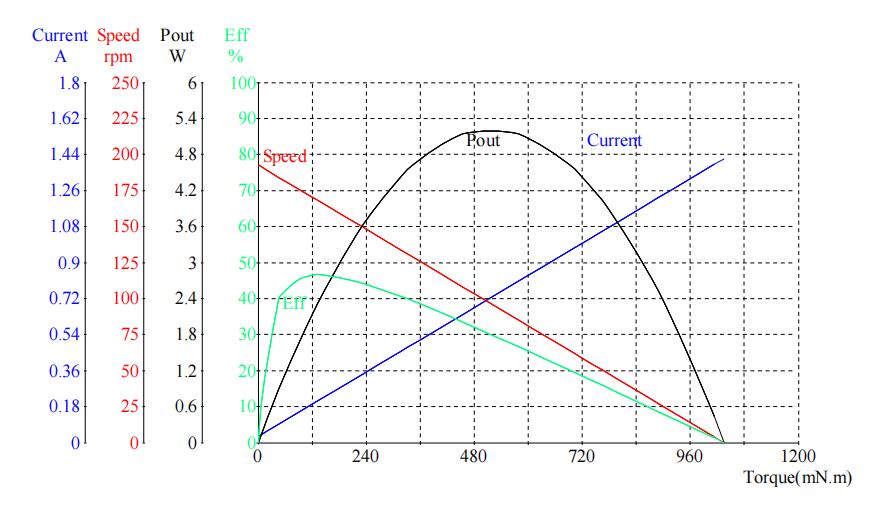

How to test the performance DC spur gear motor?

When evaluating the performance of your DC spur gear motor, you should take several factors into account, including speed, torque, and current. Connect the motor to a power source and measure the speed with a tachometer or speedometer to determine the no-load speed. Attach a load to the motor and measure the speed with a tachometer or speedometer to test the rated speed.

Attach a load to the motor and monitor the speed and current draw for the best efficiency. Adjust the load until the motor is operating at its most efficiently. It is critical to remember that when testing motors, you must take safety measures and refer to the manufacturer’s paperwork for full testing recommendations. Additionally, you might want to think about using a data capture system to document the motor’s performance for later analysis.

Conducting extensive testing is essential for assessing the effectiveness and suitability of a DC gear motor for a particular application. This involves looking at important factors such the rated torque, stall torque, rated current, and stall current. These tests help you assess the motor’s suitability for your intended usage by giving you critical information about its capabilities.

You can thoroughly assess the performance of your DC spur gear motor and identify any potential issues that may need to be rectified by looking at these features. Making sure your motor is operating at its peak efficiency can assist to increase its lifespan and prevent early failure.