What Types Brushless Gear Motor it Has?

What types of brushless dc gear motor are available?

Regarding motion control and precision engineering, Brushless DC gear motor are a driving force in various industries. These motors come in various types, each designed for specific applications; among them are BLDC planetary gear motor, BLDC worm gear motor, BLDC spur gear motor, and BLDC square gear motor.

Another criteria for categorization is the voltage. We have the bldc gear motor 24v and the brushless dc gear motor 12v. The voltage category makes it easy for engineer to know the best brushless motor on application. In this short piece, we’ll delve into the intricacies of each type, from their fundamental construction to how they work – all while highlighting their significance in different contexts.

BLDC Planetary Gear Motor: Unveiling Precision and Power

The BLDC planetary gear motor combines the exceptional performance of a brushless DC motor with the precision of a planetary gearbox. Its core features a brushless DC planetary gear motor known for its efficiency, reliability, and longevity. Because of the BLDC motor structure, BLDC planetary gear motor no needs brushes.

The magic happens when you add a planetary gearbox to the equation. Planetary gearboxes consist of a central “sun” gear, multiple smaller “planet” gears, and an outer “ring” gear. The planet gears are connected to the central shaft of the BLDC motor and rotate around it. As these planet gears engage with both the sun and ring gears, they create a compact yet powerful reduction in speed and an increase in torque.

The interaction between the BLDC motor and the planetary gearbox results in high torque, making BLDC planetary gear motor ideal for applications that require precise control and significant power. These motors find use in robotics, small CNC machines, conveyor systems, and other applications where precision and power are paramount.

BLDC Worm Gear Motor: Harnessing Efficiency Through Worm Gears

In the realm of BLDC gear motor, the BLDC worm gear motor stands out with its unique construct. Just like other BLDC motors, it begins with a brushless DC motor as its foundation. However, the key differentiator here is the integration of a worm gearbox.

A brushless DC worm gearbox consists of a worm (a screw-like gear) and a worm wheel. The worm gear is connected to the BLDC motor’s shaft, and as it rotates, it drives the worm wheel, resulting in a reduction in speed and an increase in torque. This design offers incredible efficiency and self-locking properties.

Brushless DC worm gear motor are particularly suited for applications where holding position is critical. They excel in scenarios such as automated gates, lifting mechanisms, and precision positioning systems.

BLDC Spur Gear Motor: Simplicity Meets Versatility

The BLDC spur gear motor takes a different approach to gearing compared to planetary and worm gear designs. It begins with the familiar brushless DC motor but integrates a spur gearbox.

The spur gearbox comprises cylindrical gears with straight teeth. This design simplifies the overall construction while offering versatility in terms of speed and torque. BLDC spur gear motors are often favored for their compact size and ease of installation.

They find applications in various fields, including automotive, medical devices, and home automation systems. Their straightforward design and reliable performance make them a popular choice where space is limited.

BLDC Square Gear Motor: Compact and Precise

Last but not least, the BLDC square gear motor combines the efficiency of a brushless DC motor with the precision of a square gearbox. The square gearbox design, often referred to as a right-angle gearbox, allows for compact and space-efficient installations.

These motors are highly versatile and find applications in industries ranging from robotics and automation to HVAC systems and small appliances. Their square gearbox enables them to fit into tight spaces, making them valuable in scenarios where spatial constraints are a concern.

In conclusion, BLDC DC gear motors are a diverse family of motors, each tailored to specific applications. Whether it’s the precision of a planetary gearbox, the efficiency of a worm gearbox, the simplicity of a spur gearbox, or the compactness of a square gearbox, BLDC gear motors play a pivotal role in modern industries. They drive automation, improve efficiency, and provide the torque and control necessary for various tasks. So, the next time you encounter a piece of machinery with precise motion control, a BLDC gear motor is behind the scenes, quietly but efficiently powering the motion.

What is the difference between BLDC Planetary Gear Motor and Brushed Planetary Gear Motor?

Construction and Working Principles

Brushed Planetary Gear Motor and BLDC Planetary Gear Motor share the common feature of employing a gear mechanism, often in the form of multi-stage or planetary gears. These gears are intimately connected to the motor’s drive shaft and interact with each other to regulate the motor’s speed while amplifying its output torque.

The fundamental distinction between these two motor types lies in their internal construction and how they generate motion. Brushed motors utilize brushes and commutators to create a rotating magnetic field within the motor. The brushes make physical contact with the commutator, which switches the direction of current flow in the motor’s windings. This switching generates the rotational motion of the motor.

Brushed DC Motor:

In contrast, BLDC Planetary Gear Motor operates without brushes or commutators. They rely on advanced electronic control systems to manipulate current flow in the motor phases. By precisely controlling the timing and intensity of this current, BLDC motors create a magnetic field that drives the motor’s rotation. This brushless design offers several significant advantages.

Performance Advantages of BLDC Planetary Gear Motors

1. Size and Weight:

BLDC motors are typically smaller and lighter than their brushed counterparts. This compactness is especially valuable in applications where space is at a premium.

2. Noise Levels:

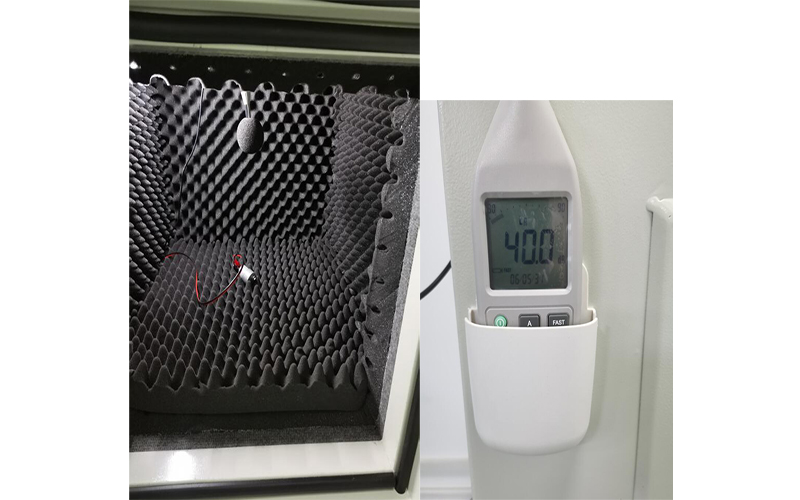

BLDC motors are renowned for their quiet operation. The absence of brushes eliminates the brush-related noise and friction, resulting in a quieter and more pleasant working environment.

3. Longevity:

BLDC motors have a longer operational lifespan when compared to brushed motors. Brushes in brushed motors are subject to wear and tear, leading to a limited lifespan. BLDC motors, on the other hand, have no brushes, so their lifespan is greatly extended.

4. Efficiency:

BLDC Planetary Gear Motors boast exceptional efficiency. The precise electronic control of the motor phases ensures that power is used efficiently, resulting in minimal energy wastage as heat.

5. Controllability:

BLDC planetary gear motor offer superior controllability due to their built-in controller into BLDC motor. This precision is particularly valuable in applications that require precise speed and position control. Brushed planetary gear motor is controlled by external encoder or external control plate.

Applications

The choice between Brushed Planetary Gear Motors and BLDC Planetary Gear Motors often hinges on the specific application’s requirements. Brushed motors are still used in various applications, particularly those with simpler operational needs and budget constraints.

BLDC Planetary Gear Motors shine in applications that demand low noise, efficiency, precision, and reliability. They are commonly found in industries such as robotics, automation, aerospace, and medical devices, where compactness, longevity, and quiet operation are essential.

To wrap it up, while both Brushed Planetary Gear Motor and BLDC Planetary Gear Motor serve as valuable components in a range of applications, the brushless design of BLDC motors offers significant advantages in terms of performance, quiety, efficiency, and longevity. When efficiency, precision, and a longer operational life are paramount, BLDC Planetary Gear Motor are preferred.