Planetary Gearheads VS Spur Gearheads

Explore the differences between planetary gearheads, spur gearheads, and worm gearboxes in our comprehensive article. Learn about their construction, applications, torque, speed, efficiency, and more to make informed engineering decisions.

Gearheads are essential components in DC gear motor, quietly playing a significant role in various mechanical systems. They amplify torque, enabling precise and powerful machine operations through gears. These devices have a broad range o f applications, from industrial machinery to robotics.

Gearheads(for DC gear motor) come in different types, each designed for specific purposes, such as high-speed tasks or high torque requirements. In this article, we’ll take a closer look at three main types: planetary gearheads, spur gearheads, and worm gearboxes.

Spur Gearheads(for spur gear motor) are the workhorses of gear technology. They have a straightforward design, where two gears team up to increase torque, making them cost-effective solutions for various applications. However, they face challenges like backlash and reduced efficiency.

Planetary Gearheads(for DC planetary gear motor), on the other hand, are more complex. They consist of an input shaft that drives a central sun gear, which, in turn, moves surrounding planet gears. This results in synchronized torque delivery and a remarkable capacity for high torque output.

Worm Gearboxes (for DC worm gear motor)are the champions of reduction ratios and self-locking capabilities. They use a unique screw-like mechanism and excel in applications demanding precision and reliability.

Get ready to explore gearheads, their applications, and their advantages. Understanding them will help you optimize your mechanical systems.

What is Planetary Gearhead?

Planetary gearheads, also called epicyclic gearboxes, are the go-to choice for many mechanical systems. They shine in situations where torque needs to be just right, and they’re a solid option among gearheads like spur gearheads and worm gearboxes.

When comparing them to spur gearheads and worm gearboxes, planetary gearheads offer something special. They’re excellent when you need to make sure that torque is delivered in a coordinated way, which is crucial for precision in machines and equipment.

Planetary gearheads are utilized in diverse appliances and machinery, such as robots, industrial equipment, and precision instruments. Their value lies in their capacity to effectively generate significant power within compact and limited spaces.

Regarding the maintenance of planetary gearheads, their inherent design makes them straightforward and dependable. These gearheads are recognized for their durability and the simplicity with which they can be maintained to ensure they function at their best.

To keep a planetary gearhead operating smoothly over an extended period, a modest amount of lubrication is typically all that’s required. Regularly applying the appropriate lubricant helps reduce friction and wear within the gearhead, ensuring it continues to function efficiently.

Moreover, periodic checks to verify that all components are in proper alignment and working order can go a long way in preventing potential issues. This proactive approach helps detect any anomalies or deviations from the expected performance, allowing for timely adjustments or maintenance.

How Planetary Gearhead Works

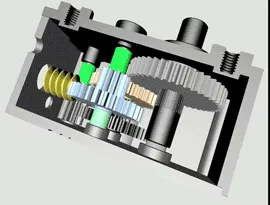

Understanding the inner workings of a planetary gearhead is essential to grasp its role in mechanical systems. It operates through a simple yet effective mechanism, comprising four crucial elements: the sun gear, planetary gears, a ring gear, and a planetary arm carrier.

The sun gear takes center stage, connected to a motor, and positioned at the core of the gearhead. Its role is akin to that of an engine, driving the entire system. In contrast, the ring gear remains fixed, providing stability and serving as a reference point.

A key aspect lies in the performance of the planetary gears. These small gears have their axes of rotation and engage in a dual movement. They spin on their individual axes while simultaneously orbiting around the sun gear, much like planets orbiting the sun in our solar system. This arrangement enables them to efficiently transmit power from the sun gear.

The planetary arm carrier acts as the output shaft of the gearhead. It collects the torque generated by the planetary gears and conveys it to the connected mechanical system.

This planetary gearhead setup, resembling the way our solar system operates, is what gives it the name “planetary.” It excels in compactly delivering substantial power and ensures precise and efficient motion control with minimal noise.

In a nutshell, the planetary gearhead’s straightforward yet effective design makes it an invaluable component in various mechanical applications, where power and precision are paramount.

The Benefits of Planetary Gearhead

Let’s dive deeper into the practical advantages of incorporating a planetary gearhead into your mechanical systems. These benefits are essential to understanding why planetary gearheads are favored by engineers and designers:

High Torque Density

Planetary gearheads are power-packed and capable of accommodating substantial torque within limited space. This means your machines can deliver robust performance, even in confined environments.

Versatile Reduction Ratios

One of the standout features is their ability to provide a wide range of reduction ratios. By using multiple housing stages, planetary gearheads offer versatility, allowing you to tailor the gearhead precisely to your application's needs. This not only enhances efficiency but can also lead to cost savings.

Exceptional Precision

Thanks to precision machining, planetary gearheads boast minimal backlash, often as low as 1 arcmin. This precision guarantees accurate and repeatable motion control, vital in applications where every movement counts.

Noise Mitigation

Operating at just 55 decibels, planetary gearheads are a boon for noise-sensitive environments. Their quiet operation fosters a more pleasant workplace and can contribute to improved safety and comfort.

Efficient Power Transmission

Planetary gearheads are designed to minimize energy losses within the gearbox. This results in highly efficient power transmission, maximizing the performance of your mechanical systems while reducing energy consumption.

Compact and Agile

Their compact dimensions and low inertia are pivotal in applications demanding rapid start-stop cycles and agile directional changes. These qualities empower machines to respond swiftly to changing requirements, enhancing overall productivity.

What is Spur Gearhead?

A spur gearhead is a vital component in the world of mechanical systems. It plays a crucial role in various applications due to its simplicity and effectiveness. Unlike other gearheads, the design of a spur gearhead is straightforward, consisting of a DC motor and a series of gears enclosed in a sturdy frame.

One notable characteristic of spur gearheads is their uncomplicated design, which involves smaller gears meshing with larger ones. This mechanical configuration enables efficient torque transmission without the need for intricate mechanisms.

Compared to its counterparts like planetary and worm gearheads, spur gearheads are known for their simplicity. They are often chosen for applications that require lower reduction ratios and a cost-effective solution. While they may not offer the same versatility as planetary gearheads or the self-locking capabilities of worm gearheads, spur gearheads find their place in various scenarios.

Typical applications for spur gearheads encompass a variety of everyday scenarios, making them the unsung heroes of mechanical systems. From automated paper towel dispensers that serve us in public restrooms to conveyor systems that efficiently transport goods, spur gearheads quietly facilitate our daily lives. Their ability to provide uncomplicated and reliable torque transmission ensures these devices perform their tasks with ease and precision.

When it comes to maintenance, the good news is that keeping spur gearheads in top-notch condition is generally a straightforward process. Spur gearheads benefit from periodic lubrication of the gears. This simple maintenance routine ensures smooth and efficient operation, prolonging the gearheads’ lifespan and allowing them to continue working reliably.

How Spur Gearhead Works?

Spur gearheads operate with a simplicity that belies their effectiveness. The core of their design involves a series of gears mounted on parallel shafts, slightly offset from each other. This uncomplicated yet ingenious arrangement plays a crucial role in transforming motor speed into torque.

When the DC motor springs to life, it initiates a cascading effect. The smaller gear attached to the motor’s shaft starts to turn. As it rotates, it seamlessly meshes with a larger gear. This meshing of gears is where the magic happens – it efficiently converts the motor’s speed into torque, creating a powerful mechanical output.

One remarkable feature of spur gearheads is their maintenance of a single contact point between gears, which bears the brunt of the load. This design ensures efficient torque transmission and reliability.

For applications that require further reduction in speed and an increase in torque, spur gearheads can be enhanced by adding multiple gear stages within the gearhead. Each stage provides an additional layer of gear reduction, resulting in progressively lower output speed and higher output torque.

Spur gearheads are celebrated for their cost-effectiveness and straightforward design. They shine brightest in scenarios where low torque and low RPM are the order of the day, such as automated paper towel dispensers and other applications where precision and efficiency are essential.

The Benefits of Spur Gearhead

Spur gearheads, with their elegant simplicity, offer a range of benefits that make them a preferred choice in various applications. Let’s delve into these advantages:

Simplicity

Spur gearheads boast a straightforward design that simplifies installation, making them suitable even for restricted spaces. This ease of integration is a key factor in their versatility.

Constant Speed Drive

Planetary gearheads excel in providing precise speed adjustments with consistent velocity. This attribute is crucial in a wide range of applications demanding reliable and constant motion, ensuring your machinery operates seamlessly.

Reliability

Spur gears are known for their steadfast reliability. They rarely slip during operation, and their inherent durability significantly reduces the risk of premature failure. This reliability is a hallmark of their design.

Cost-Effective

The simplicity of their design not only aids in installation but also allows for cost-effective manufacturing and customization. This cost-efficiency is a significant advantage in budget-conscious projects.

Efficiency

Spur gearheads exhibit high power transmission efficiencies, reaching up to an impressive 99%. This means that minimal energy is lost during the transmission of power, contributing to their efficiency

Low Noise

In comparison to single-stage planetary gearheads, spur gearheads generate significantly less noise. This feature enhances their suitability for noise-sensitive applications where quiet operation is essential.

Versatility

Spur gearheads offer versatility beyond their simple design. They can accommodate the mounting of sensors or potentiometers, providing flexibility in various applications where precise control is needed.